What are the Facts?

Cannabis has been used to treat pain since as far back as 2900 B.C. Plants have natural values in the baring oils, they get very powerful and strong medicine when concentrated with extraction. The most powerful is the flower oil when extracted properly with nature being in mind. Тhe Flower Oils contain a mixture of natural compounds that are extremely beneficial for the body functions: 104 different cannabinoids, also called oleoresins; 3,000 terpenes also known as essential oils; Flavonoids are natural substances with variable phenolic structures; nitrogenous compounds; common plant molecules.

Table of Contents

ToggleBelow are 16 simple facts about Cannabis:

- 1 acre of hemp produces oxygen as 100 acres of forest.

- 1 acre of hemp can produce the same amount of paper as 16 acres of trees.

- Hemp can produce 3 times more paper than wood.

- Hemp grows for 4 months, the tree grows for 20-50 years.

- Hemp acts as a radiation trap.

- Hemp can be grown anywhere in the world and needs very little water.

- Hemp oils are natural pesticides, it can protect itself from insects and it does not need pesticides to grow.

- Hemp is an ideal plant for making textiles, ropes, bags, shoes, hats, etc.

- Cannabis oil reduces the effects of chemotherapy and radiation in the treatment.

- Cannabis is used in treatment of at least 250 diseases such as rheumatism, heart, epilepsy, asthma, stomach, insomnia, psychology and spine diseases.

- The protein value of hemp seed is in between the highest.

- Hemp is cheaper to produce than soybeans.

- Cannabis-fed animals do not need hormone supplements.

- All plastic products can be made from hemp, and hemp plastic is very easy to recycle.

- If the car body is made of hemp, it will be 10 times stronger than steel.

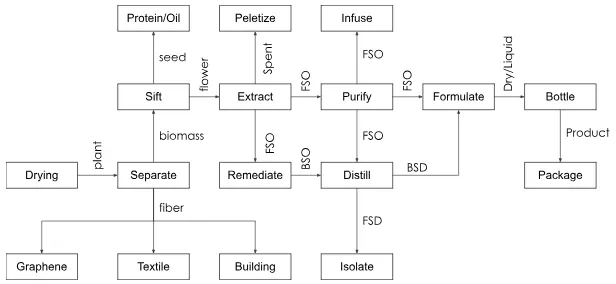

What is the Process?

A proper process would increase the value of the products to the customer and will more likely have that customer returning back for the same products and services over and over. This is how the PURE5™ process offering is creating values in your products and overcomes the crowded marketplace general offering.

Pre-Process

Align the most cost efficient and gentle to the biomass process to prepare your raw material for further processing. Plant pre-processing refers to the initial stages of handling and preparing crops or plants after they are harvested. This includes activities like cleaning, sorting, and packaging the harvested plants for distribution to markets or further processing facilities.

Process

The processing uses various methods and techniques to convert raw plant materials into useful products. Cannabis is mostly often used as raw material for pharmaceutical drugs or supplements. Plant processing in the pharmaceutical industry involves extracting active compounds from plants to create medications. Techniques like extraction, distillation, and purification are used to isolate and concentrate the desired compounds.

Types of extraction systems

There are several different types of cannabis extraction systems to be considered. We will cover the basics of hemp Extraction devices below:

CO2 Extraction Equipment

CO2 (carbon dioxide) is a common solvent used for extraction of cannabinoids and terpenes. CO2 extraction requires highly pressurized CO2 into supercritical conditions which occur over 340 atmospheres pressure in order to dissolve the cannabinoids out. CO2 produces cannabinoid crude rich on waxes and it needs to be cleaned up with other solvents.

CO2 as a solvent is widely used in food processing and essential oil production because it is non-volatile and leaves little traces. CO2 is also an option for extracting plant terpenes that retain the flavor profile of the original plant. This is important for vape products and other full-spectrum products that are popular with hemp enthusiasts. Although the terpenes are extracted in sub critical mode the process usually takes over 5 hours and not always can be cost effective.

Ethanol Extraction Equipment

Ethanol provides a versatile extract and it can be used for a variety of cannabis and hemp end products mostly derived from crude extract converted into distillate. When it is properly performed, ethanol extraction deliverses crude oil in most cases known as Rick Simpson oil. To minimize extraction wax and lipids the extraction should be performed at cryogenic temperatures of -40C. The extraction is mostly done in centrifuges since due the high boiling point the centrifuge is the quickest first stage miscella (solvent + cannabinoids) recovery. Still the solvent loss can be as high as 15-20% during that process as the material can be still wet after centrifusion. After the extraction there is a filtering as during the centrifuge stage there are particles in the miscella. Those are removed by a series of particle filters.

Hydrocarbon Extraction Equipment

Every extraction delivers a different type of product, it is the same with hydrocarbons mostly known as the perfect dab product. If you need to create live resins, diamonds, butter, crumble, etc. hydrocarbon extraction is an excellent option for you. The use of hydrocarbons (propane, butane, or hexane) helps preserve the authentic flavor of each strain, which is a combination of cannabis flavonoids, terpenes, and cannabinoids. There is so much interest in the products that hydrocarbon extraction creates that is why it is becoming very popular. The disadvantage of hydrocarbon extraction is the cost of installing the equipment required to perform hydrocarbon extraction in C1D1 rooms.

Solventless extraction equipment

Solvent-free extraction equipment mechanically separates cannabinoid-rich trichomes from plant biomass. This separation uses either dry sifting or cold water and/or ice and vigorous agitation to break the trichomes from the cannabis flower. The trichomes are then filtered from the biomass and water and used to create a high quality hash product. The negatives are the need for very high quality flowers for best results, low yields and high labor intensive process. Also depending on your starting material post processing may be required to remove waxes using solvent which defeats the purpose of the solventless process.

R134A aerosol extraction

This method has been used and popularized since 2000 by PURE5™ Extraction. It is a much better option than the described 4 methods as it unifies their advantages and eliminates their disadvantages. Due to the low boiling point it works in a similar manner as CO2 and it is easy to remove and recover 100%. It is a non-flammable fluorinated hydrocarbon gas which allows much safer and less expensive setups of very large volumes. Compared to ethanol it doesn’t draw wax and lipids and does not require winterization or extraction under cryogenic temperatures. Generally safe, fast and cost efficient process. R134A aerosol extracts at room temperature conditions live resin and full spectrum extracts with all of its medicinal benefits at low cost and high quality. Due to the energy efficiency and faster process the system and operation cost of R134A aerosol cannabis extraction process is much lower than CO2, ethanol, hydrocarbon or even the solventless extractions.

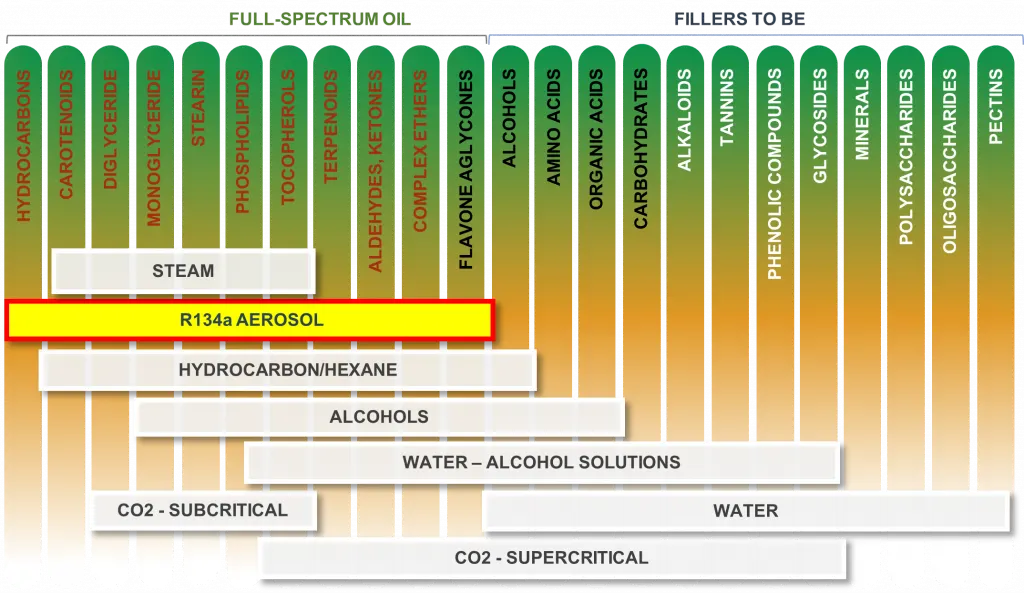

Post process

The magic of extraction is in the solvent. Each solvent brings unique properties into the process related to its selectivity to dilute various organic compounds. That is why every extraction method produces different type of extract and the solventless methods which are mostly mechanical separation methods have least selectivity and purity. It is vital for the post-processing to know what process you are using for extraction as the post-processing is different for each type of crude extract obtained.

In the diagram below we list the common solvents used in extraction with the common constituents they dilute from the plant. It is important to notice that the active compounds in cannabis are oils and the best solvents for the field should be considered extracting those components.

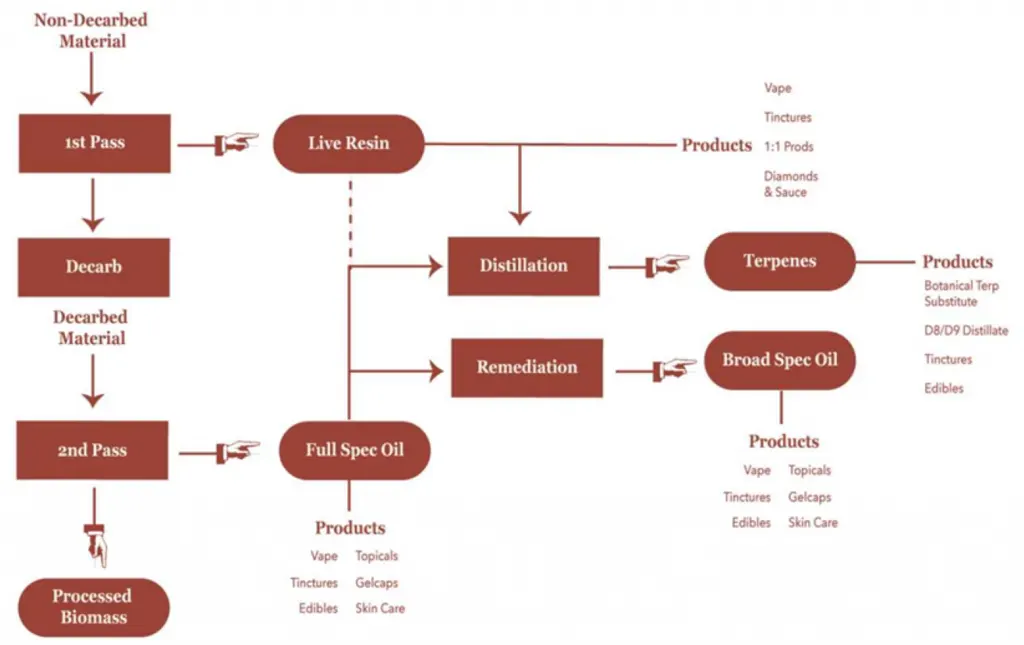

Depending on the extracted compound from the plant the extract can go directly to a product if the consistency includes only the Full Spectrum compounds or undergo winterization and additional filtration when CO2 or Ethanol is used. In addition, for the CBD market THC may need to be mitigated to compliance levels. After the waxes and THC are removed the extract can be distilled and further converted to isolates used in pharmaceutical formulations.

Maintaining high antioxidant activity

Antioxidants are molecules that can help your body fight off harmful free radicals, which have been linked to health conditions like diabetes and cancer. The cannabis plant is rich in flavonoids such as anthocyanins. Anthocyanins belong to a parent class of molecules called flavonoids. They can occur in all tissues of higher plants, including leaves, stems, roots, flowers, and fruits. They are odorless and moderately astringent. An astringent (sometimes called adstringent) is a chemical that constricts the body tissues. With PURE5™ technology we preserve the antioxidant value of those compounds in maintaining the naturality of the extract.

Maintaining high Bioavailability

There have been multiple ways to extract cannabis oils on the market and every method created different output. An essential part of keeping the bioavailability of the extract is to repeat the natural consistency of the oil in the plant and maintain neutral PH limiting oxidation, vital low temperature compounds as enzymes, phenolic and flavonoids and amount of the active component loss during the process as terpenes and cannabinoids. With PURE5™ technology we increase the value of those compounds in maintaining the bioavailability of the extract.

Mitigating Mold and Yeast

The data collected is clearly showing the PURE5™ Extraction with R134a aerosol mitigates the mold and yeast over 1000 times from the contaminated starting material. This provides another natural and clean way to remediate the contaminated plant while converting in strain specific terpene rich Hash ResinTM extract.

Preserving Natural Color

Making your extraction strain specific requires a full understanding of the flower, the solvent and the process involved. Using well grown strains, extracted at room temperature with our extremely inert solvent that does not alter the original components is the most pristine way of extracting the plants. With PURE5™ technology we preserve the natural color and presence of those quality compounds in maintaining the naturality of the extract.

Economics

The Time to Market (TTM) is as important as the CapEx and OpEx for the success of the business. Utilizing CO2, ethanol, rosin and butane needs lengthy pre and post processing which requires stock of a product to be maintained to satisfy demand. Utilizing the PURE5TM single run process can put a product on the market within 24 hours. Pelos is an example chart of how multiple products can be created from each fraction the method can produce.

What the PURE5™ process creates is an unique type of extract containing all terpenes and cannabinoids that differs by values from every other extract obtained. We simply called the extract “Hash Resin” which means hash drug made by compressing and processing parts of the cannabis plant, typically focusing on flowering buds containing the most trichomes and resin is a solid or highly viscous organic substance of plant or synthetic origin that is typically convertible into polymers.

The below discussion is usually kept as the proprietary extractor knowledge and no extraction company will rarely discuss with customers. The reason for that is that the numbers differ between systems and vendors and since the extraction companies are focused on selling their machines most often shorten the process explanation especially in numbers.

Below is a parallel in between the Capital Expense (CapEx) and Operational Expense (OpEx) that an extractor should know. In those numbers only the hard cost of operation (power and loss) is included without taking into account labor and Time to Market.

| Parameter | CO2 | Ethanol | Butane | R134a |

| CapEx | $450,000.00 | $125,000.00 | $250,000.00 | $125,000.00 |

| Facility Compliance | $50,000.00 | $100,000.00 | $200,000.00 | $0.00 |

| 10L Volume | 3 | 3 | 3 | 3 |

| particle size | 0.5 | NA | NA | NA |

| Extraction Time | 120 | 40 | 40 | 60 |

| Efficiency | 90% | 85% | 95% | 97% |

| Recovery Time | 180 | 180 | 60 | 60 |

| Solven per run | 12 | 10 | 8 | 8 |

| Pressure | 310 | 1 | 6 | 9 |

| Recovery Efficiency | 90% | 85% | 90% | 99% |

| Solvent Loss | 1.2 | 1.5 | 0.8 | 0.08 |

| Solvent Cost | $10.00 | $7.00 | $10.00 | $7.00 |

| Cost per Run | $12.00 | $10.50 | $8.00 | $0.56 |

| Power | 20 | 10 | 10 | 2 |

| Energy cost | $6.00 | $3.00 | $3.00 | $0.60 |

| Total per Run | $18.00 | $13.50 | $11.00 | $1.16 |

| Run Cost per Month | $3,240.00 | $2,430.00 | $1,980.00 | $208.80 |

| Cost to Install | $500,000.00 | $225,000.00 | $450,000.00 | $125,000.00 |

The only extraction we have not discussed above is the “solventless” Rosin press. That extraction is not really solventless since it may oftenly to go through ethanol as a secondary step for wax removal that comes from the melted trichomes. Rosin winterization is more likely necessary to remove impurities, like wax, left behind in the rosin. By removing the impurities in the rosin, it keeps and looks fresh for longer and also increases in THC content.

Making Products

Drugs

Drugs have medicinal, recreational, or therapeutic effects, and they are obtained through legal means.The drugs are prescribed by healthcare professionals to treat specific medical conditions. They include antibiotics, painkillers, antidepressants, and medications for chronic diseases like diabetes and hypertension.

Full Body Plant Extracts

Those type of extracts are referring to extracts derived from various parts of plants, including leaves, stems, roots, flowers, and seeds. These extracts can be used for medicinal, therapeutic, or cosmetic purposes. The specific parts of the plant used for extraction and the extraction methods employed can significantly influence the properties of the resulting extract.

Herbal Supplements

Herbal supplements are dietary supplements made from plants or plant extracts. They are used for various purposes, including improving health, supporting specific bodily functions, or addressing specific health concerns. Herbal supplements have been used for centuries in traditional medicine systems around the world, and they continue to be popular due to the belief in their natural and holistic benefits. Here are some key points about herbal supplements.

Summary

What to consider

Choosing the right equipment for your business is crucial for its success. The right tools can enhance efficiency, productivity, and overall performance. Here are some steps to help you choose the right equipment for your business:

1. Assess Your Needs:

- Identify Requirements: Determine what equipment is necessary for your business operations. Consider immediate needs as well as future growth.

- What type of equipment do you need?

- How will it be used in your operations?

- What are your production or service demands?

- Are there any specific features or capabilities you require?

- Budget Constraints: Understand your budget limitations. Balance quality and features with affordability.

2. Research Thoroughly:

- Compare Options: Research different brands and models. Compare features, specifications, and prices.

- Read Reviews: Look for customer reviews and testimonials. Real experiences can provide valuable insights.

- Consider Longevity: Invest in equipment that will last. Consider the reputation of the manufacturer and the expected lifespan of the product.

3. Compatibility and Integration:

- Ensure Compatibility: Make sure the new equipment integrates well with existing systems. Compatibility issues can lead to inefficiencies.

- Scalability: Choose equipment that can scale with your business. Avoid solutions that might quickly become obsolete.

4. Quality and Reliability:

- Quality Assurance: Opt for reputable brands with a history of producing reliable equipment. Quality products often come with warranties and excellent customer support.

- Reliability: Equipment downtime can be costly. Choose reliable devices with low maintenance requirements.

5. Energy Efficiency and Environmental Impact:

- Energy Efficiency: Energy-efficient equipment can reduce utility costs and is environmentally friendly. Look for Energy Star ratings or similar certifications.

- Environmental Impact: Consider the environmental impact of the equipment. Choose products and manufacturers with eco-friendly practices.

6. Training and Support:

- Training Needs: Evaluate the training requirements for your staff. Some equipment might require specialized training.

- Customer Support: Consider the availability and responsiveness of customer support. Good support can be invaluable if issues arise.

7. Future Upgrades and Maintenance:

- Upgradability: Check if the equipment allows for upgrades or modular additions. This can extend the lifespan of your investment.

- Maintenance: Assess the maintenance needs and costs. Some equipment might require regular servicing.

8. Legal and Safety Compliance:

- Compliance: Ensure the equipment complies with cannabis legal regulations and industry standards. Non-compliance can lead to legal issues.

- Safety: Prioritize safety features, especially for equipment that involves potentially hazardous operations.

9. Consider Renting or Leasing:

- Financial Flexibility: Leasing or renting equipment can provide financial flexibility, especially for businesses with budget constraints.

- Stay Current: Leasing allows you to upgrade to newer equipment easily, ensuring you always have access to the latest technology.

10. Get Professional Advice:

- Consult Experts: If you’re unsure, consider consulting with specialists or experts in the field. They can provide tailored recommendations based on your business needs.

By following these steps and taking the time to thoroughly research and assess your options, you can choose the right equipment that aligns with your business goals and contributes to its success.

Strategy for Success

- Diversify your process flow – assess your market

- Fully utilize plant biomass and waste in your process

- Select a process with shorter TTM and lowest OpEx

- Build outstanding brand with most natural appearance

- Use the highest quality products in your formulations

- Apply the state of art science in your process to preserve values

- Elevate human health with properly formulated botanical blends

- Consider low CapEx when select equipment – lease

- Position your process to be scalable

- Assess the Quality and Reliability of the equipment

Share your success with PURE5™. We offer a cutting edge worldwide exclusive technology that can deliver a post winterized terpene rich oil in one gentle extraction pass. The oil is fully strain specific, highly potent and ready to formulate in products right off the extraction.

For inquiries contact:

Dr. George Stantchev, CEO

(602) 992-0744