As society increasingly recognizes the potential benefits of cannabis, the industry has seen explosive growth. Among the crucial aspects that contribute to the industry’s expansion is cannabis processing.

Table of Contents

ToggleIt’s an umbrella term that incorporates various stages involved in transforming the raw cannabis plant into a consumable product of high-quality, brimming with desired traits.

This article aims to present an in-depth view of cannabis processing, emphasizing its importance, methods, stages, and the best practices and considerations needed in the procedure.

What is Cannabis Processing?

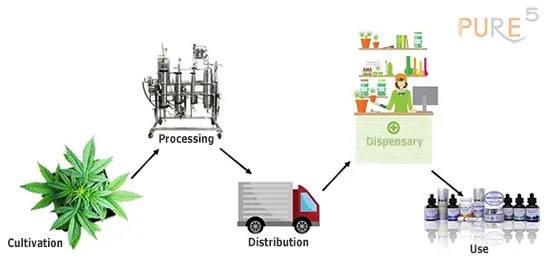

Cannabis processing refers to the conversion of raw cannabis plant material into refined products that users can consume or use.

This transformation includes numerous steps, such as harvesting, drying, curing, extraction, refinement, formulation, and packaging, each of which plays a significant role in determining the quality and effectiveness of the final product.

What is the Purpose of Cannabis Processing?

The ultimate goal of cannabis processing is to create products that deliver the desired effects and meet the needs of a broad range of consumers.

These products vary widely, from smokable flowers and tinctures to edibles, topicals, and concentrates.

Each product type requires a specific method of processing to ensure it maintains the integrity of the bioactive compounds present in the cannabis plant, including cannabinoids and terpenes.

How is Cultivation related to Cannabis Processing?

How is Cultivation related to Cannabis Processing?

Cannabis cultivation is the first step in the journey of the cannabis plant. It involves growing the plants under controlled conditions, often in a greenhouse or indoor setting, and ensuring that they receive the correct amounts of light, water, and nutrients. The quality of cultivation directly affects the processing stages and the final product.

For instance, the cannabinoids content, which includes THC and CBD, primarily depends on how well the plants are grown.

What are the Different Stages of Cannabis Processing?

Cannabis processing involves a series of steps, each contributing to the development of a high-quality, consumable cannabis product. Let’s delve into these stages in detail.

Harvesting

Harvesting

The process of cannabis refinement begins with harvesting, where mature cannabis plants are cut down. The timing of the harvest is crucial as it can significantly affect the potency and flavor profile of the final product.

Different trimming techniques and equipment are used during harvesting to separate the valuable buds from the rest of the plant.

- The buds are carefully removed from the stems.

- Unwanted leaves surrounding the buds are trimmed.

- Trimming can be done manually or using specialized machines for efficiency.

Drying and Curing

The drying process involves reducing the moisture content in the cannabis buds, usually done in a controlled environment with proper air circulation. Different methods and equipment can be used, such as air drying in a room with controlled temperature and humidity.

Curing, on the other hand, involves storing the dried plant material under specific conditions for a period. It’s a slow process that allows the buds to develop a rich and smooth flavor. Curing techniques include:

- Jar curing: This method involves placing the dried buds in airtight jars and storing them in a cool, dark place.

- Vacuum sealing: This method allows for longer storage periods and preserves the cannabinoid and terpene content effectively.

Trimming

Once the cannabis plants have undergone drying and curing, the next crucial stage of processing is trimming.

This stage entails the careful removal of excess leaves and stems from the cannabis buds, which could otherwise result in a bitter taste and harsh smoke.

The aim is to leave only the cannabinoid-rich flowers, thus enhancing the overall quality and aesthetics of the final product.

- Manual trimming is a time-honored practice that requires skilled labor, often involving specialized tools like bud trimming scissors While this method is applauded for its precision and ability to preserve bud quality, it is quite labor-intensive and time-consuming.

- Consequently, many processing facilities opt for automated trimming machines, which, while faster, must be operated with care to avoid compromising bud integrity.

Extraction

Cannabis extraction is a pivotal step of cannabis processing as it separates the vital cannabinoids and terpenes from the plant material.

These compounds, such as THC (tetrahydrocannabinol) and CBD (cannabidiol), are what give cannabis its renowned medicinal and recreational properties. The goal here is to ensure the extraction process preserves these bioactive compounds as much as possible.

Extraction methods typically fall into two categories:

- Solvent-based extraction employs chemicals like ethanol or supercritical carbon dioxide (CO2) to dissolve the cannabinoids and terpenes from the cannabis plant material. These methods are known for their efficiency and ability to yield a high concentration of active compounds. However, they require substantial investment in specialized equipment and expertise.

- Solventless extraction techniques rely on heat and pressure to squeeze the precious compounds out of the cannabis flowers. While these methods might not produce the same yield as their solvent-based counterparts, they are appreciated for their purity, maintaining the full spectrum of the cannabis plant’s properties without the risk of residual solvents.

Refining and Purification

Once the extraction process is complete, the resulting cannabis extracts still contain impurities like waxes, lipids, and chlorophyll that need to be removed. This refining stage, often involving processes such as winterization, filtration, or distillation, ensures that the final product is pure and safe for consumption.

- Winterization is a process wherein the crude extract is mixed with ethanol and frozen, facilitating the precipitation and filtration of impurities.

- Following this, cannabis distillation techniques are employed to further purify the cannabis extracts. These techniques rely on the different boiling points of the compounds, allowing for their effective separation. It’s worth noting that the equipment used in this stage, such as rotary evaporators and vacuum chambers, can be quite complex and require experienced operators.

Decarboxylation

Decarboxylation is a vital stage in cannabis processing that often goes unnoticed despite its significance. It involves the application of heat to the cannabis material, activating the cannabinoids and enhancing their potency.

Specifically, it converts THCA (tetrahydrocannabinolic acid), a non-psychoactive compound, into the psychoactive THC, thus rendering the cannabis effective when used in products like edibles, tinctures, or topicals.

This process can be performed using simple equipment like baking trays for small-scale operations or using specialized decarboxylation ovens for industrial-scale production. The duration and temperature of decarboxylation are critical factors to consider, as they directly impact the final product’s potency and overall quality.

Formulation and Product Development

Once the cannabis extracts have been refined and decarboxylated, they’re ready for formulation into a wide range of products. This stage marks the transformation of the activated cannabis extract into user-friendly forms like oils, tinctures, edibles, topicals, or vape cartridges.

Formulation involves combining the cannabis extracts with other ingredients to create specific product profiles. For instance, a CBD tincture might include carrier oils and flavorings, while a topical cream may contain cannabis extract mixed with moisturizing and therapeutic agents. This stage of the process also often includes rigorous testing to ensure the right concentrations and compositions.

Packaging and Distribution

The type of packaging used depends on the form of the product. Edibles might be packaged in child-resistant bags or boxes, while tinctures and oils may come in dropper bottles. Labels are also a critical aspect of packaging, providing vital information such as the product name, ingredients, THC/CBD content, and the batch number for traceability purposes.

Once the products are packaged, they are ready for distribution. Depending on local regulations, these products can be transported to retail dispensaries, pharmacies, or directly to consumers through an online platform.

Compliance and Regulation

Throughout every stage of the cannabis processing chain, compliance with local and national regulations is paramount.

Different regions have varying laws about the cultivation, production, sale, and use of cannabis products.

Producers must ensure they comply with these laws, which often involve obtaining the necessary permits, adhering to strict product testing requirements, and maintaining transparent records of their operations.

These regulations ensure that cannabis products are safe for consumption and that their production doesn’t negatively impact the environment or community. While compliance can be challenging, it is essential for the legitimacy and longevity of any cannabis business so everyone should take it seriously..

Future Trends in Cannabis Processing

As the cannabis industry continues to flourish, new techniques, technologies, and advancements are emerging that are revolutionizing cannabis refinement.

Machine learning and AI are now being used to automate parts of the cultivation process, including irrigation, fertilization, and disease detection.

Innovative extraction methods are being developed to increase yield and efficiency, with a growing focus on solventless techniques that reduce the environmental impact and improve the quality of the extracts.

There is also a trend towards more personalized cannabis products, with companies developing ways to customize cannabinoid and terpene profiles to cater to individual consumer preferences.

Predictions for the future of cannabis processing largely focus on technological advancements. As the sector matures, it’s expected that automation will become even more integral, improving efficiency and scalability for producers.

Additionally, as research into the health benefits of cannabis continues, there may be an increased focus on medical-grade products, which would require more precise and controlled processing techniques.

How to Choose Cannabis Processing Equipment?

Choosing the right equipment for cannabis processing is crucial to ensure efficiency, product quality, and regulatory compliance. Here are some tips for making the best choice:

- Understand your needs: Before purchasing any equipment, make sure to have a clear understanding of your processing requirements, including the scale of your operation, the types of products you intend to produce, and any regulatory requirements you must meet.

- Research and compare: Don’t settle for the first option you find. Instead, spend time researching different equipment providers, comparing their offerings, and reading customer reviews.

- Consider cost vs. quality: While budget constraints are often a reality, it’s important not to sacrifice quality for cost. High-quality equipment might require a larger upfront investment but can save money in the long run by reducing downtime and maintenance costs and improving product quality.

- Look for versatility: As the cannabis industry evolves, so too might your processing needs. Choosing versatile equipment that can accommodate different processing techniques or product types will provide more flexibility for your business in the future.

- Choose a reputable manufacturer or provider: When selecting a provider, consider their reputation within the industry, their customer service, and their ability to provide ongoing support and maintenance.

With PURE5™, a revolutionary manufacturer of cannabis and hemp processing and extraction equipment, you can be sure that you will elevate your operations.

Our portfolio includes an array of advanced machines, from extraction and remediation systems to cannabis distillation equipment, all designed to preserve the natural potency of botanicals.

More than just machinery, our CBD and THC extraction solutions provide superior efficiency, yielding better end products at a lower cost compared to traditional CO2, butane, propane, or ethanol methods.

With a commitment to innovation and quality, PURE5™ has set a new benchmark in the industry, avoiding high temperatures or harmful solvents to ensure minimal degradation and deliver the purest form of natural plant vitality. Join the revolution with PURE5™.

What are Various Products Created from Cannabis Processing?

Cannabis processing opens the door to a myriad of products, each serving distinct purposes and markets. Here’s a brief glimpse at some of the most prominent offerings:

Medicinal Products

Through precise extraction and refinement, cannabis can be transformed into various medicinal products. These include CBD oil for pain and anxiety management, THC oil for appetite stimulation and nausea reduction, and even a blend of both for balanced effects.

- CBD Capsules: These are easy-to-consume pills containing concentrated CBD oil. They’re favored for their convenience and dosage accuracy.

- THC Tinctures: These are liquid extracts that can be administered under the tongue for rapid absorption.

- Topical Creams: Infused with cannabis extracts, these creams can potentially alleviate skin conditions and muscle pain.

Recreational Products

cannabis refinement also fuels the recreational market with products like cannabis-infused edibles, vape cartridges, and smokable flower.

- Edibles: These are food and beverage items infused with cannabis extract, offering a longer-lasting, albeit delayed, effect compared to smoking or vaping.

- Vape Cartridges: These contain concentrated cannabis oil that can be vaporized using a compatible device.

- Smokable Flower: Although the most traditional form of cannabis, even smokable flower undergoes processing to dry and cure the plant for optimal flavor and potency.

Industrial Products

- Hemp Textiles: Hemp fibers can be spun into durable and eco-friendly textiles.

- Biofuels: Hemp biomass can be converted into a sustainable biofuel, offering a greener alternative to fossil fuels.

- Construction Materials: Hemp can be processed into ‘hempcrete,’ a durable and eco-friendly construction material.

Conclusion

Cannabis processing is a complex but essential part of the cannabis industry, transforming raw cannabis plants into a diverse array of consumable products.

Each stage of the process, from cultivation and harvesting to extraction, refinement, and packaging, plays a crucial role in determining the quality, safety, and effectiveness of the final product.

By understanding and carefully managing each step of this process, cannabis producers can ensure they are delivering high-quality, compliant products that meet consumer expectations. As the cannabis industry continues to grow and innovate, so too will the techniques and technologies used in cannabis processing, promising even greater efficiency, quality, and product diversity in the future.

Whether you are a seasoned cannabis processor or a newcomer to the industry, staying informed about the latest trends, technologies, and regulations is crucial to success.

How is Cultivation related to Cannabis Processing?

How is Cultivation related to Cannabis Processing? Harvesting

Harvesting