Table of Contents

ToggleBefore Investing in Cannabis

Before you invest in any cannabis extraction operation, make absolutely sure you know the answers to all the important questions and understand the available choices. We’ve addressed the importance of these choices, from understanding the extraction equipment to working with potential equipment suppliers.

Planning and researching helps you to make some important business decisions. The initial research should include investigating the following areas:

- Market Opportunity: Research the whole market. Are there gaps that can be filled? Is it a product or service? Is it quality, price or variety?

- Target audience: Who actually will consume your product? Is it for medical or recreational use? Or both? For vaping or an infused market?

- Products: What type of cannabis product do you have capability to make? What is doing well in the market today? Does your product have its own niche? What do you need to improve?

- Extraction Method: Every extraction method delivers a different product. Knowing the actual type of product you plan to sell will help you to decide which extraction method and equipment to invest in. You can talk to an expert who can help you make the right decisions toward your goals for creating strain specific extracts.

- Laws and Regulations: Each state has its own laws and regulations governing the manufacture of cannabis products. Consult a professional familiar with the laws in your area.

Determining the specific equipment to purchase for an extraction operation requires answering the questions above and understanding how common solvent and non-solvent extraction techniques work and what type of product each can deliver.

Types of cannabis extracts

Crude Oil

Crude oil is a product of non selective solvent extraction when along the actives there are other plant residues and organic compounds. It is the first step out of CO2 or room temperature ethanol extraction.

Rick Simpson Oil

A type of crude oil extract obtained with ethanol extraction.

Live Resin

Extracted Fresh plant with rich terpene profile and preserved acid cannabinoid forms.

Full Spectrum Oil

Post winterized crude containing all the cannabinoids and terpenes in natural combination.

Distillate

Distilled Full spectrum oil to remove terpenes and dyes leaving only the cannabinoids in high concentration usually higher than 90%, characterized with light color.

Hash Resin

Full spectrum oil containing all terpenes and cannabinoids, extracted from fresh or cured dry herb.

Diamonds

Crystalized THCA form obtained with hydrocarbon extraction.

Butter

Cannabinoid concentrate with high wax content mostly obtained from fresh plants with hydrocarbon extraction.

Bubble/Rosin Hash

Type of “solventless” extract where the trichomes of the flower are separated either by sifting or crushing in iced water then the kief is pressed on a hot rosin press until it melts in an oil resin form.

Types of solvents

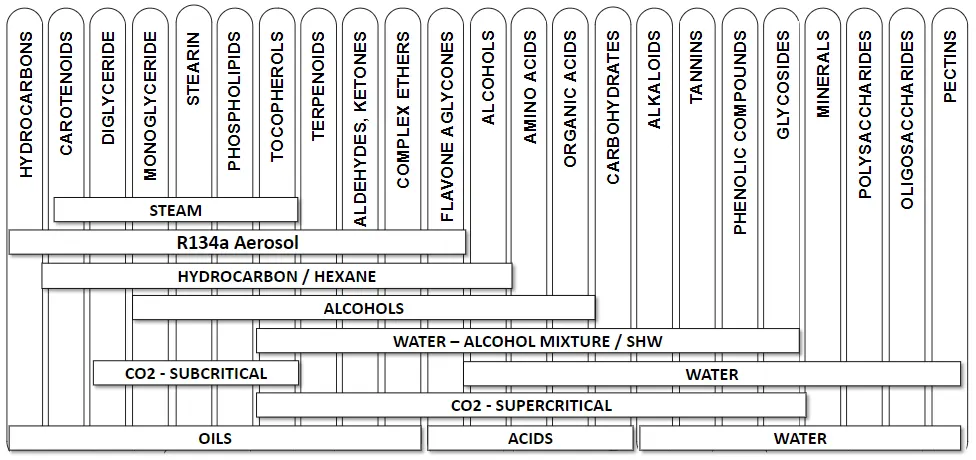

The magic of extraction is in the solvent. Each solvent brings unique properties into the process related to its selectivity to dilute various organic compounds. That is why every extraction method produces different type of extract and the solventless methods which are mostly mechanical separation methods have least selectivity and purity.

In the diagram below we list the common solvents used in extraction with the common constituents they dilute from the plant. It is important to notice that the active compounds in cannabis are oils and the best solvents for the field should be considered extracting those components.

Types of extraction systems

There are several different types of cannabis extraction systems to be considered. We will cover the basics of hemp Extraction devices below:

Ethanol Extraction Equipment

The next stage is separation of the extract from the solvent, second stage solvent recovery. The recovery is a process close to a refined liquor distillation. The most common recovery is done by falling film distillation systems (FFD). The miscella flows through thin heated pipes where the ethanol is evaporated and the extract drained down. Unfortunately tue the high boiling point of the ethanol this recovery is not 100% as well. The extract has a high concentration of ethanol still that needs to be removed in a third stage recovery. That recovery is done in rotary evaporators that more precisely remove the ethanol from the extract. All above is a high temperature labor intensive process.

The setup of the ETOH extracting equipment is fairly straightforward and must be performed under C1D2 conditions while the ethanol storage for over 50L is regulated. Ethanol can be recovered and reused for multiple cycles, making the process scalable, and repeatable. One downside of ethanol extraction is that traces of the alcohol solvent are left in the final product and it is not 100% pure. Also ethanol can be reused so many times, usually no more than 10 and then disposed of which makes that method a costly solution in the long term.

Equipment for CO2 extraction

CO2 (carbon dioxide) is another common solvent used for extraction of cannabinoids and terpenes. CO2 extraction requires highly pressurized CO2 into supercritical conditions which occur over 340 atmospheres pressure in order to dissolve the cannabinoids out. CO2 produces cannabinoid crude rich on waxes and it needs to be cleaned up with other solvents.

CO2 as a solvent is widely used in food processing and essential oil production because it is non-volatile and leaves little traces. CO2 is also an option for extracting plant terpenes that retain the flavor profile of the original plant. This is important for vape products and other full-spectrum products that are popular with hemp enthusiasts. Although the terpenes are extracted in sub critical mode the process usually takes over 5 hours and not always can be cost effective.

What kind of CO2 extractor should someone invest in? It depends on the initial size of your operation, your budget, the space available, and the final product you want to create. One of the main disadvantages of CO2 extraction is the high cost of the equipment because the process is complicated and needs expensive machinery and proper know-how for the workers and the slow process does not give you great yields. Second disadvantage is that it requires a fairly sophisticated lab to post-process the extracted resin, for example winterization and distillation in order to produce marketable products.

Equipment for Hydrocarbon extraction

Hydrocarbon extractors are generally cheaper than CO2 and more expensive than ethanol extractors. But due the high flammability and explosion danger the extraction systems are mostly smaller sizes and manual rather fully automated. This makes hydrocarbon extraction a good choice for start-ups and companies looking to produce derivatives in small batches. A skilled lab technician can achieve cannabinoid concentrations of up to 70-80% at very high purities and create a variety of specific marketable products.

The disadvantage of hydrocarbon extraction is the cost of installing the equipment required to perform hydrocarbon extraction in C1D1 rooms. The equipment required is also not cheap, and the amount of hydrocarbons allowed on-site at one time is regulated, making it difficult (legally) to scale up production. The labor involved is at high cost due the extremely high flammability of the process that always leaves residues altering the taste of the extract.

Due to the danger of inhaling and combustion all systems above ethanol, hydrocarbon and CO2 must use closed loop design, so the system is completely sealed and solvent is fully recovered. Environment monitored for leaks with proper on site ventilation.

Solventless extraction equipment

Solvent-free extraction equipment mechanically separates cannabinoid-rich trichomes from plant biomass. This separation uses either dry sifting or cold water and/or ice and vigorous agitation to break the trichomes from the cannabis flower. The trichomes are then filtered from the biomass and water and used to create a high quality hash product.

The negatives are the need for very high quality flowers for best results, low yields and high labor intensive process. Also depending on your starting material post processing may be required to remove waxes using solvent which defeats the purpose of the solventless process.

R134A aerosol extraction

Using R134A aerosol one can extract at room temperature conditions live resin and full spectrum extracts with all of its medicinal benefits at low cost and high quality. Due to the energy efficiency and faster process the system and operation cost of R134A aerosol cannabis extraction process is much lower than CO2, ethanol, hydrocarbon or even the solventless extractions. Extraction with R134a aerosol is done at room temperature under an airless environment allowing the closed-loop system to easily separate the natural plant oils from the raw material without temperature stress and oxidation.

The method has been approved since 1994 by the FDA and the European Union Authorities and has been certified as GRAS (Generally Recognized As Safe). Widely used in industry, medicine, aerospace, military and pharma. The extraction process is patented by PURE5™ extraction in multiple implementations.

Summary

If you’re excited about investing in your own hemp operation, finding an extraction equipment supplier who can help you plan, design, build, and obtain all safety and zoning permits can be a huge help in the process. Some suggestions:

- Do some research to educate yourself and talk to industry experts to get enough information to select the right technology.

- Ask vendors questions, participate in demos and try the products to understand what you will be making and how the market will accept it.

- Find an ally in the field that can provide you the support and you can grow the business organically and develop your brand customers can recognize.

How Can We Help?

Speak with our experts to find out what kind of cannabis extraction machinery and knowledge you need to reach your business goals.

###

602-284-8038