A Comprehensive Guide to State of Art Technologies

Table of Contents

ToggleOverview

Cannabis oil extraction is a transformative process that converts raw cannabis or hemp material into valuable liquid strain specific extracts. The highest quality extracts on the market are Live Resin extracted at ambient temperature and Hash Resin maintaining the original strain terpenes. The quality of the extraction process is crucial and directly impacts the efficiency, safety, and overall purity of the final product. High-quality and specialized equipment is paramount for ensuring a successful and pure extraction process, underscoring its significance in producing top-notch cannabis extracts.

Evolution in Extraction

The Rise of Innovative Solutions in Cannabis

The cannabis and hemp industry is witnessing a rise in innovative solutions aimed at enhancing efficiency and product quality. At the forefront of this evolution is PURE5™ Extraction, introducing a unique approach that revolutionizes cannabis and hemp extraction. Committed to safety, speed, and cost-effectiveness, PURE5™ is setting new standards in the ever-evolving landscape of extraction technology.

Understanding Cannabis Equipment

Extraction Technologies

Currently the industry is utilizing various extraction methods, including CO2, ethanol, butane, propane, hydrocarbon, supercritical fluid, ice water hash, rosin press, and low-pressure R134a aerosol extractions. Those can be simply separated at solvent based and solventless extraction methods. Each method is delivering a different type of end product.

Extraction Methods

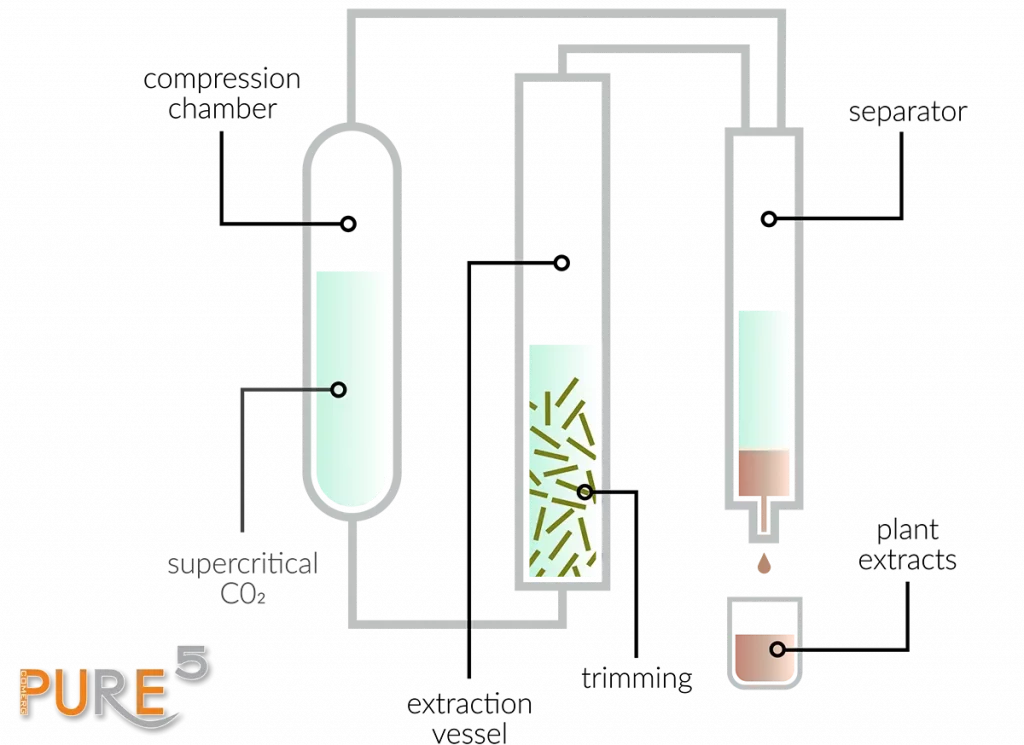

CO2 Extraction

CO2 extraction stands out as an efficient method that employs carbon dioxide in a sub or supercritical state. The supercritical state allows CO2 to behave as both a liquid and a gas, making it a good solvent for extracting cannabinoids. The process involves pressurizing and exposing CO2 to high pressures, transforming it into a supercritical fluid. This fluid is then used to separate cannabinoids and other compounds from the plant material. CO2 extraction is known for its flexibility, versatility, and the ability to produce quality extracts after extensive post processing and without leaving residual solvents.

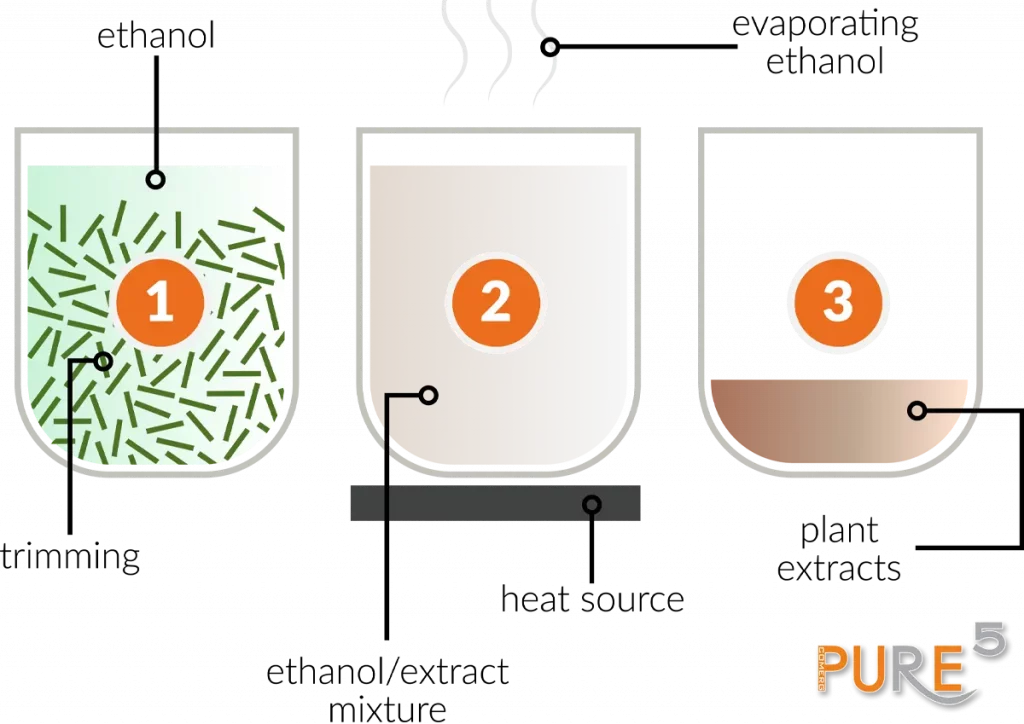

Ethanol Extraction

Ethanol extraction is a very common method that uses ethanol as a solvent to dissolve cannabinoids and other desirable compounds. This process involves soaking the plant material in ethanol, allowing the solvent to absorb the cannabinoids. The solution is then filtered to separate the plant material from the liquid. Ethanol, being a polar solvent, can effectively capture a wide spectrum of cannabinoids and other compounds. This method is recognized for its simplicity and ability to produce extracts with a full spectrum of compounds. Production efficiency is low due the extensive manual procedures and loss of a solvent.

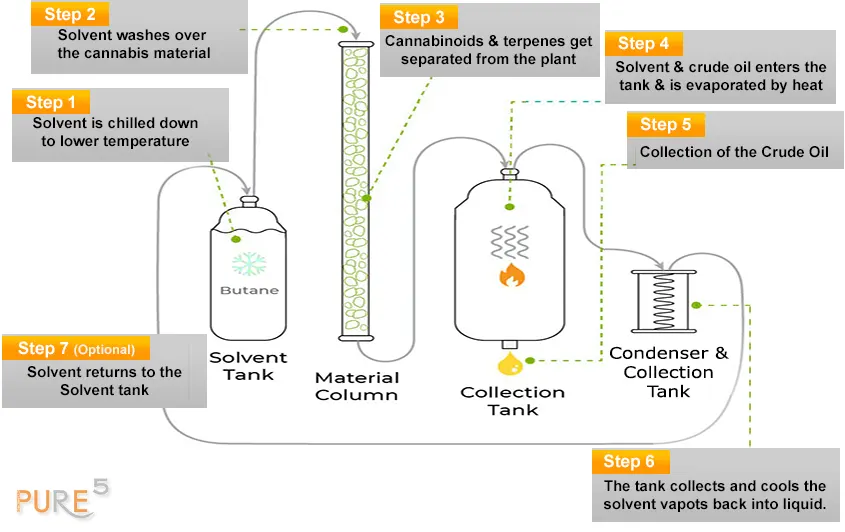

Hydrocarbon Extraction

This extraction method utilizes various hydrocarbons such as butane and propane to extract cannabinoids. The process involves passing the hydrocarbon solvent through the plant material to dissolve and extract the desired compounds. Subsequently, the solvent is evaporated, leaving behind a concentrated cannabis extract. While these methods can be efficient, they require careful control of the extraction process to ensure the removal of any residual solvents, which can be hazardous. Additionally, hydrocarbon extraction is known for its ability to preserve terpene profiles in the final product.

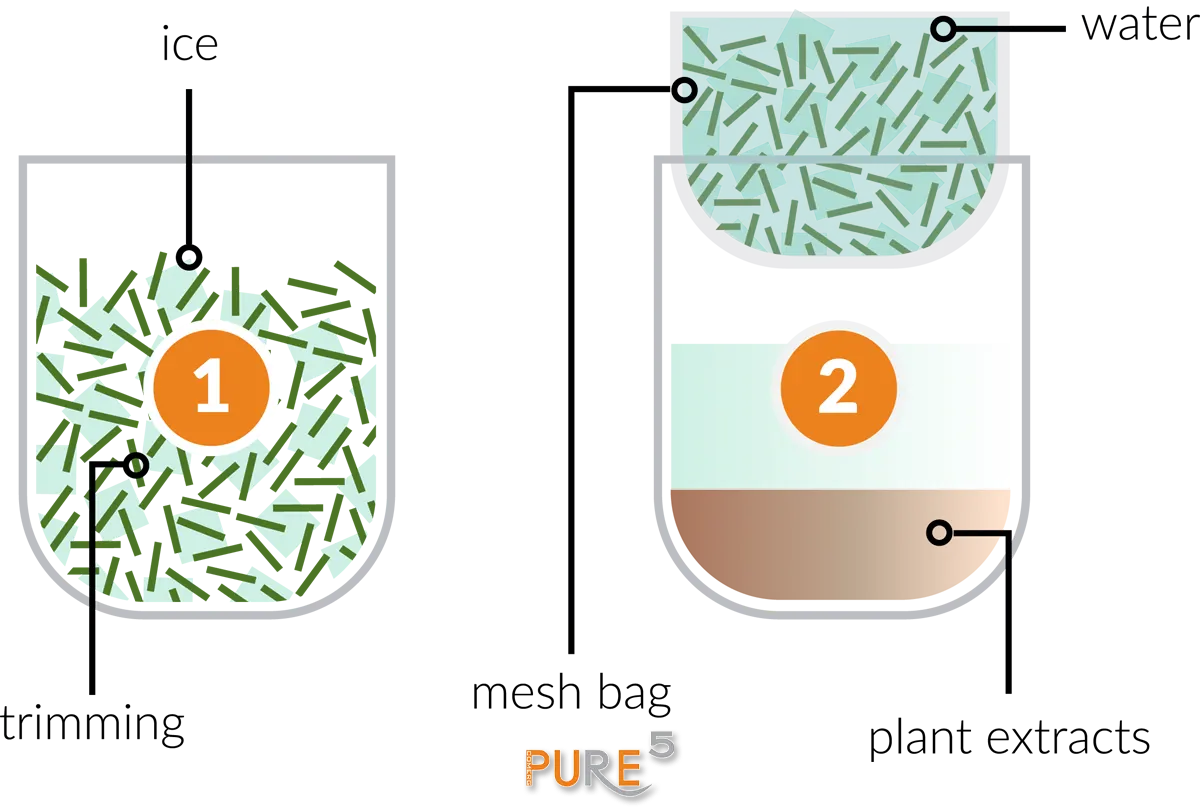

Ice Water Extraction

Ice water hash extraction is a solventless method that relies on water and ice to separate trichomes from the plant material. The process involves agitating the cannabis or hemp material in ice water, causing the trichomes to detach. The mixture is then filtered to collect the trichomes, which contain cannabinoids and terpenes. The collected trichomes then are pressed at high temperature press to extract the oil. This method is popular for its low cost equipment and it does not involve the use of other solvents. The resulting product is often referred to as “bubble hash” and is known for its natural appearance.

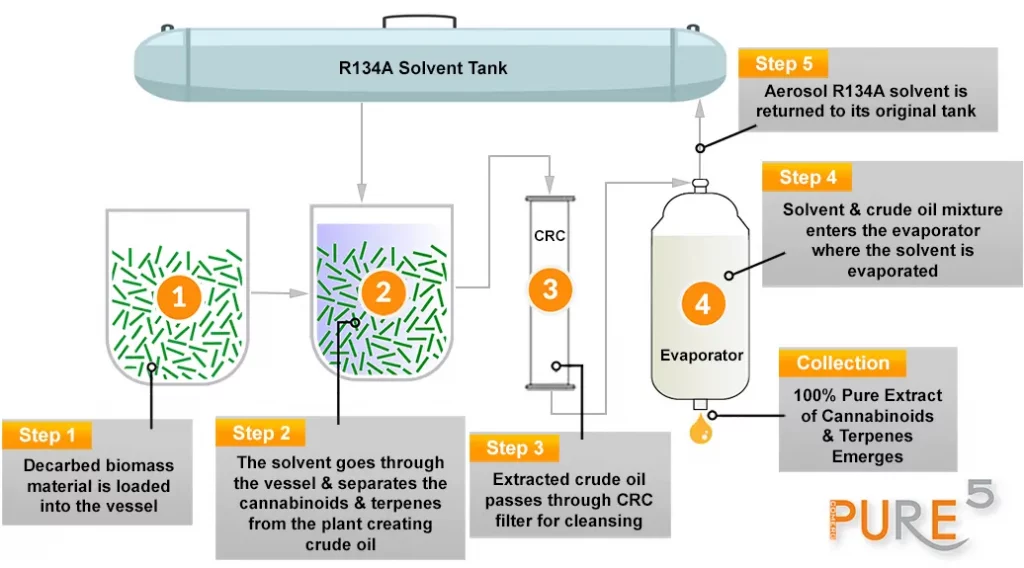

R134a Extraction

Solventless extraction, exemplified by PURE5™, is a method that stands at the pinnacle of innovation in cannabis extraction. This groundbreaking approach prioritizes purity, efficiency, and cost-effectiveness avoiding external solvents. R134a aerosol extraction systems are operating at ambient temperature, PURE5’s method preserves the plant’s integrity, offering a safer, more cost-effective, and efficient solution. This unique approach ensures the preservation of cannabinoids and terpenes, delivering a superior end product at a fraction of the cost, establishing PURE5™ as the preferred choice for businesses aiming to redefine their cannabis extracts.

Essential Equipment in Cannabis Processing

THC Remediation Equipment

Mold & Yeast Remediation Equipment

Mold and Yeast Remediation Equipment is crucial for maintaining the quality and safety of cannabis extracts. This equipment helps eliminate molds and yeasts that can negatively impact the final product, ensuring compliance with industry standards and regulations.

Lab Equipment

Lab Equipment in the cannabis industry spans various crucial machines, enhancing the extraction and analysis processes. This includes Wipe Film Distillation Units, Crystallization Reactors, Gas Chromatography Units, Ultrasound Nano Emulsification Units, and Vacuum Ovens. Wipe Film Distillation Units play a role in separating compounds efficiently, Crystallization Reactors facilitate the crystallization of substances, and Gas Chromatography Units aid in analyzing the chemical composition of extracts in minutes. While not extraction units, this equipment is integral to refining and quality control in the extraction process.

Farming Equipment

Farming Equipment plays a vital role in the cannabis industry, providing the foundation for high-quality cultivation and preprocessing. The Hemp Harvester is a key component in harvesting cannabis and hemp plants efficiently, ensuring that the raw material for extraction is of the highest quality. The stick and sift separator fractions the biomass in ready to extract fraction, fiber and seeds.

The PURE5™ Advantage

Unique Extraction Experience:

PURE5™ extracts are raw unaltered by heat strain specific resins that deliver a most natural holistic effect, providing liquid flower experience in the resin and every aspect of the products created with it.

Safer, Faster, and More Cost-Effective

PURE5™’s technology ensures safety, speed, and cost-effectiveness, surpassing traditional extraction methods.

Low-Pressure Extraction Equipment

The low-pressure extraction equipment manufactured by PURE5™ Extraction stands out with simplicity and is a game-changer, producing higher yields at a lower cost compared to other alternatives.

Plant to Product Cycle

Cannabis Production Cycle

Managing the production cycle is crucial for maximizing the processing results. The flow begins with cultivation, where cannabis plants are grown to maturity. After cultivation comes the harvesting stage, where the plants are carefully collected and separated from the fiber. The next step is processing, where extraction equipment comes into play to obtain the most natural extract.

The next stage is post processing where the oils and other remaining plant fractions are refined into industry known raw materials. Here all the lab equipment is utilized to isolate cannabinoids and terpenes via distillation and obtain isolates with proper reactors. The final stage is product formulation and packaging that can be in various forms depending on the delivery method, as nano tinctures, vapes, cosmetics or tablets. Understanding each stage in the production cycle, from seed to shelf, is essential for businesses aiming to produce high-quality cannabis extracts at the lowest possible production cost.

Full Spectrum Oils

Quality Cannabis Extraction Equipment Options

Diverse Equipment Options

When looking for quality cannabis extraction equipment, businesses should check out the various options in the market. Exploring these options is crucial to understand the different types and technologies available. It helps businesses make informed decisions that suit their specific needs in the cannabis and hemp industry. The criterias in such a choice is speed, cost, quality and return of the investment.

Choosing High-Quality Extraction Solutions

Choosing top-notch extraction solutions, like those from PURE5™, offers key benefits. These solutions bring safety, speed, and cost-effectiveness to the extraction process. Opting for high-quality equipment ensures reliable and efficient operations, producing top-tier product quality. This strategic choice keeps businesses ahead in innovation, making their cannabis and hemp extraction processes effective and streamlined.

Hemp Processing Machines

Hemp processing plays a crucial role in various industries, providing versatility in applications ranging from wellness products to industrial materials. The significance lies in the extraction of valuable compounds from hemp plants, contributing to the creation of diverse end-products like hemp oil, CBD extracts, graphene, fibers, proteins, fertilizers and more. Cutting-edge hemp processing machines, exemplified by PURE5™, elevate efficiency by incorporating latest achievements of the science. These machines use innovative methods that ensure a thorough extraction process, preserving the plant’s natural values. By adopting state-of-the-art equipment, businesses can enhance their production processes, producing high-quality hemp oil with increased efficiency and consistency.

Common Queries in Cannabis Extraction

Safety of the Extraction Process

Safety is paramount in the extraction process, and PURE5™ prioritizes it through advanced technology. The innovative systems, such as R134a aerosol extraction units, operate safely at ambient temperature and low pressure, minimizing risks associated with extreme conditions. The proprietary solventless extraction method further eliminates the use of external solvents, ensuring a secure and controlled environment for operators and consumers alike.

Comparative Analysis

A detailed comparative analysis highlights the superiority of advanced technology over traditional extraction methods. Traditional approaches involve harsh solvents, extreme temperatures, and longer processing times, compromising the final extract’s quality. In contrast, advanced technology, exemplified by PURE5™, revolutionizes the extraction landscape. The use of R134a aerosol extraction systems ensures a gentle yet efficient process preserving natural potency, resulting in superior product quality, faster extraction times, and overall cost-effectiveness.

Adapting to Scale

PURE5™ caters to the diverse needs of both small and large-scale cannabis and hemp processing operations. Its scalable extraction equipment provides efficiency and affordability for smaller operations, while larger-scale businesses benefit from scalability without compromising quality. Whether a startup or an established enterprise, PURE5™ ensures its extraction solutions align with specific business requirements, fostering growth and success.

Isolating Cannabis Terpenes

Conclusion

In summary, this guide has delved into the revolutionary aspects of cannabis extraction, highlighting significant technological advancements, prioritizing safety, and ensuring top-notch product quality. It’s an encompassing exploration that encourages businesses to embrace innovations in extraction technology, urging them to consider cutting-edge solutions like PURE5™. By actively adopting and integrating such advancements, businesses position themselves at the forefront of the ever-evolving cannabis and hemp industry, ensuring continued success and growth.

FAQ Section:

Advanced technology, exemplified by PURE5™ Extraction, ensures a safer, faster, and more cost-effective process, delivering superior end products.

Explore various reliable extraction equipment options, including PURE5™, to meet your cannabis and hemp processing needs.

Low-pressure extraction, as utilized by PURE5™, proves superior, yielding higher results in less time compared to high-pressure CO2 methods with no solvent residues.

Yes, advanced equipment, including PURE5™, caters to both small-scale and large-scale cannabis and hemp processing operations.

Isolated Hemp Terpenes, such as those offered by PURE5™, are a natural, high-quality product extracted without solvents, pesticides, or heavy metals, preserving the essence of the plant.