The State of the Market

There have been a good decade with experience in the cannabis market in regards to processing. Starting from the Rick Simpson Oil (RSO) to clean distillates (Clear) and reaching the heights of Live Resin and nicely made Bubble Hash. For all those oils varios technologies were used that produced various clarity of extract. We are at the point that the market understood the foggy future of CO2 in ethanol in cannabis extraction. The challenge still remains who will produce the nicest Live Resin, Butter or diamonds and those are in the hydrocarbon mixtures: butane, propane and R134a.

Table of Contents

Toggle

The solubilities of every cannabinoid and other phytochemicals as well as the consistency of the final product are important factors that need to be considered when selecting a method of extraction. The viscosity of cannabis oil results in binding various solvents to the table; therefore, it is important to consider the toxicity, affinity, and temperature profile of the selected solvent being used. The efficiency of conventional methods of extraction is as well dependent on the solvent of choice. The solvents used to extract cannabis can be divided into three groups depending on their dielectric constant: non polar, semi polar and polar solvents. That also refers to what volatile or other phytochemicals they can bring to the mix and how those to be dealt with.

Curing

Extremely important for the quality of the cannabis oil is the curing process. Curing is the final post-harvest procedure that allows for the actual development of the maximum flavor in the cannabis plant. The best temperature and humidity for curing are at 18 °C and 60% RH for 14 days. Also it has been a tradition to keep the trimmed flowers in a can for up to 4 weeks in a dark environment while opening the lid every day for about 6 h. At temperatures between 15–21 °C and 45–55% humidity, enzymes and aerobic bacteria will be in the optimum condition to break down undesired sugars and degrade minerals. Drying the curing the unpleasant odor can be eliminated and as well alleviate the throat irritation that some clients are concerned while smoking or vaping concentrates. It can also extend the lifespan of the cannabis product by reducing the likelihood of mold growth. Moreover, curing is needed in order to enhance the potency of cannabis by increasing the concentration of THC, CBN and other minor cannabinoids.

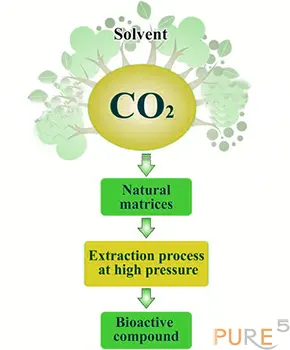

Solvent CO2

The downside of the CO2 extraction is its selectivity and the necessary post processing with ethanol in order to winterize the oil obtained that very oftenly contains over 40% other phytochemicals commonly referred as waxes. The other disadvantage is the need of grinding the material to fine powder which requires strict filtering and very often filter maintenance. The entire process is heavy on gear and recovery if it has to be a closed loop.

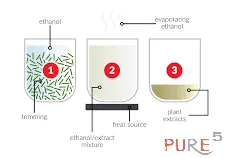

Solvent Ethanol

The negatives are that along those cannabinoids extracted other phytochemicals are sugars, wax and lipids. In order to minimize them in the extraction a cryogenic ethanol extraction is processed where the solvent is chilled to -40C to limit its solubility. With that the yield and associated expense with the process goes significantly up in cost. The other down side of the method is that the solvent loss is over 10-20% and the consistency of the recovered ethanol is changing with each extraction, therefore and the end product.

Solvent Hydrocarbon

Hydrocarbon extractors are generally cheaper than CO2 extractors. Hydrocarbon extraction is a suitable option for start-up businesses interested in creating derivatives in limited quantities, due to its unique properties. A skilled lab technician can achieve cannabinoid concentrations of up to 80% at very high purities and can tailor butane and propane to create a variety of specific marketable products.

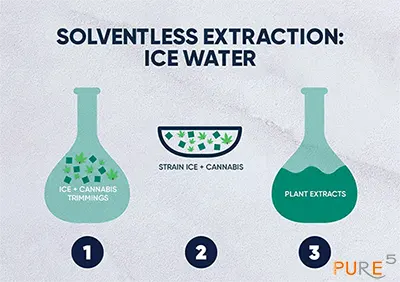

Solventless

In a search for perfection, well established solventless methods such as dry-sifting, water extraction, and rosin press extraction are becoming very popular. Dry sieve extraction produces a powder called Kief with a potency of approximately 35–50% THC. To extract trichomes from dried cannabis, the dry-sieving method involves striking the material against a mesh screen, causing the trichomes to separate and drop off. The final product is pressed under extensive heath and pressure and converted to oil. While water extraction and solventless extraction are two methods for obtaining THC and CBD from cannabis, they each have their own limitations. Water extraction involves placing cannabis in a mesh bag and immersing it in ice water, then filtering the trichomes through screens and collecting the final product, known as water hash or bubble hash. However, this method is time-consuming, labor-intensive, and yields are low, making it difficult to scale up for industrial production.

PURE5™ Aerosol

A much better option that does not require exposure of the material and therefore the oil to extreme conditions is implemented by PURE5™ in their aerosol solvent extraction. This method ensures that all cannabinoid and terpenes are extracted at room temperature conceiving all vital plant values as enzymes and aerobic bacteria are in place and the curing process will properly continue to break down undesired sugars and degrade minerals.

PURE5™ offers gentle production of Live Resin and full spectrum oils containing all medicinal benefits while keeping the cost of the process low. The cost of aerosol cannabis and hemp extraction equipment offered by PURE5™ is way lower than CO2, Ethanol, hydrocarbon or even some bubble hash extractions. Even the extraction is done at room temperature, allowing all natural compounds to separate and fully recover the solvent.

The system is evacuated from air to avoid any oxidation during the process, then the aerosol gas is slightly pressurized and passed through the plant loaded in the extraction vessel, then the aerosol is collected in a recovery tank, leaving only full-spectrum cannabis oil in the collector. This extraction method is completely safe, non flammable and non-toxic and not harmful to human health. This extraction method has been approved by the FDA in 2001 and the European Union in 1996 and has been certified as GRAS (Generally Recognized As Safe).

Conclusion

The extracts produced are extremely vital, rich in terpenes and cannabinoids, with light color and present the complete plant experience when utilized in products. For 9 years in cannabis we had only positive responses on the experience of the oils and products made with the PURE5™ process.

PURE5™ offers a complete process tutorial for creating unique raw materials for your infused products within 24 hours. You can fulfill your orders literally the same day with minimum Time To Market. Due the extremely safe and low cost process the lab can be setup with minimum compliance allowing very little investment to start making exceptional raw products: Isolated terpenes, high-terpene Live Resin, high-terpene Full Spectrum Oil, Broad Spectrum oil, high-terpene Distillate, high-terpene Dab Wax (diamonds) and butter.