In general, THC remediation is the process of lowering THC (tetrahydrocannabinol) levels to meet regulatory or quality goals.

There are a variety of remediation methods for this cannabinoid THC removal process, including most conventional chromatography. Common questions are: Which one of these THC removing methods is the most efficient, economically sustainable, and profitable?

- Dilution is an often applied solution. Medium-chain triglycerides (MCTs), such as hemp seed oil or even palm oil, are often used to keep those THC levels within legal limits.

- Crystallization is the most commonly used method. After “decarboxylation” (heating the solvent to convert CBDA to CBD), CBD readily crystallizes over 85% potency. Crystallization also does an extremely good job of sterilizing insecticides.

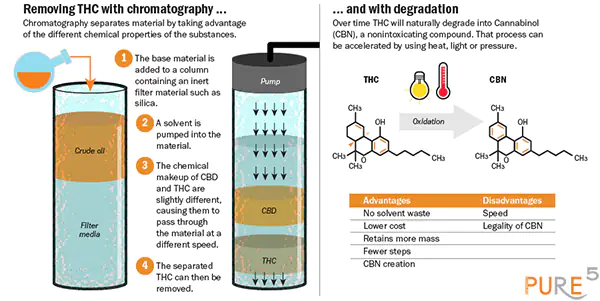

Flash chromatography is one of the common THC removing methods and remains one of the widely used tools for remediation today. Special polymer resins and large amounts of solvents are used in this process. Supercritical fluid chromatography has evolved into a subset of flash operations. Significant solvent savings appear compared to traditional systems.

- There are a few additional techniques like Molecularly printed polymer (MIP) technology. MIP uses certain polymer resin specific only for cannabinoid molecules. These techniques hold the THC or THCA molecule to the resin with a weak attractive force.

- Other similar techniques use solvents to extract cannabinoids in preferentially acidic (CBDA, THCA) or neutral (CBD, THC) forms. Finally, some techniques use actual fractional distillation to separate CBD and THC.

All of these THC remediation techniques or systems work relatively well, but scalability, operating costs, and loss rates must be also considered. PURE5™ goal is to provide the best THC remediation technology with the best THC compliance in a single system. Incorporating proprietary technology to support the highest efficiency, product quality and profitability, our background research has resulted in the best solutions to revolutionize the THC remediation industry.

If companies want to improve the quality of their end products or use highly efficient equipment for remediation to increase production without significant losses, PURE5™ technology can meet these needs. We degrade THC naturally and are solventless. We offer 4 THC Remediation options in different standard sizes that are easy and fast to install and will significantly increase your bottom line in the THC Remediation and Extraction Industry.

Flash chromatography is one of the common THC removing methods and remains one of the widely used tools for remediation today. Special polymer resins and large amounts of solvents are used in this process. Supercritical fluid chromatography has evolved into a subset of flash operations. Significant solvent savings appear compared to traditional systems.

Flash chromatography is one of the common THC removing methods and remains one of the widely used tools for remediation today. Special polymer resins and large amounts of solvents are used in this process. Supercritical fluid chromatography has evolved into a subset of flash operations. Significant solvent savings appear compared to traditional systems.