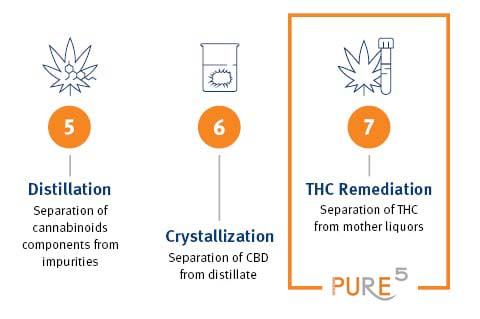

There have been a lot of terms used in accordance with the hemp compliance as example T-Compliant which means that the total levels of the THC are below the compliant level of 0.3% or 0.2% as example. Then the new term T-Free started to pop up in relation to the use of some new high techs allowing the complete removal of THC from the oil or we call that the “remediation process”.

Let’s start with the more established THC removal by separation. The most oftenly done separation is performed by Liquid Chromatography. It is the slowest and most cost prohibitive process since chromatography requires large capital investment (CapEx) and high operational expense (OpEx). There are various Chromatographies by the process and resolution.

The lowest cost and lowest resolution process is the Flash Chromatography (FC), followed by the Moving Bed Chromatography (MBC) and the most advanced and heist cost is the Centrifugal Partition Chromatography (CPC). The purpose of all chromatography is to isolate all chemicals by phasing them in a different sequence and draining them from multiple outlets or by time shift so they are separated at the end.

In chromatography two or more solvents are often used which have to be stocked and appropriate permits obtained as most of those solvents are sold under permit and regulated. Then a need for additional solvent recovery equipment should be provisioned per solvent due their aggressive nature and if GMP is required cross contamination should be monitored.

Conversion between cannabinoids influenced by heat have been known for years. For example the most common conversion is the THCa to THC and CBDa to CBD. That conversion happens every time the flower is burned. Another conversion is the dekay of THC over time as an example a study shows that THC decay every year with around 10% and more likely is oxidized to CBN. This conversion is usually enzymatic with the influence of the aerial oxygen.

Ever since there are a lot of claims that through intense heat the THC is transformed to CBN and this is the way to go on a large scale in order to remediate the problematic component, although in that case also the loss of the CBD is so great that in most cases defeats the purpose. The loss of volume and active ingredients have been seen around 20 to 30%.

The THC remediation by conversion without intense heat is a proprietary method for PURE5™ where the molecule of the THC is transformed by oxidation and or wave frequency influence to other cannabinoids. The 5L unit PURE5™ produces consumes only 250W of energy and can convert the THC in other non psychoactive cannabinoids with rates from 0.06% per hour to around 1.5% per hour.

Since no solvent is involved the cost to run the 5L PURE5™ THCF remediation system is only the consumed power. With a 250W system it will be 6kWh/day or $0.72 cent a day to remediate 1-2kg of material. Overall the cost of remediation of a liter of oil is going to be under a penny.

###

George Stantchev, PhD

(602) 992-0744

pure5extraction.com