In this guide you will be introduced to the operational intricacies of the fully automated 50 Liter Max R134a aerosol plant extractor from PURE5™. This model is the preferred choice over the last year, seamlessly combines high efficiency, full automation, and more advanced features for an effortless cannabis extraction process.

Machine Overview

Similarities are noted between the 50 Liter Max and its predecessor, the 20 Liter Max. However, a notable enhancement has been introduced – the incorporation of a built-in CRC filter. This composite media filter allows for the precise refinement of extracts, accommodating specific requirements such as color, wax, pesticides, and THC filtration. While the size closely resembles the 20-liter model, the 50-liter version offers additional expansion of the extractors, a separation vessel, and a receiver vessel. Compared to the 20L model that takes 2-3 lb per cycle the 50L model can extract 8-10 lb per cycle. The extraction cycle is typical between 20min to 60 min on all the units utilizing R134a aerosol.

Getting Started

Filling the Machine

- The extraction process begins by opening the lid and removing the filter basket (cartridge). Each extractor fits two cartridges. Fill the cartridges with plant material and insert in the extractor. Once the extractor is loaded secure the lid and the 50L machine is ready for operation.

Starting the Extraction

- PURE5™ 50 Liter Max is fully automated closed-loop system. Following the material loading, the machine detects the vessel closures and is enabled to operate. The operation begins with a simple press of a button. The first step is to remove the residual air from the vessels and then the extraction starts. During the extraction the machine’s visual graphic interface provides real-time insights into the ongoing plant extraction process.

Control Interface

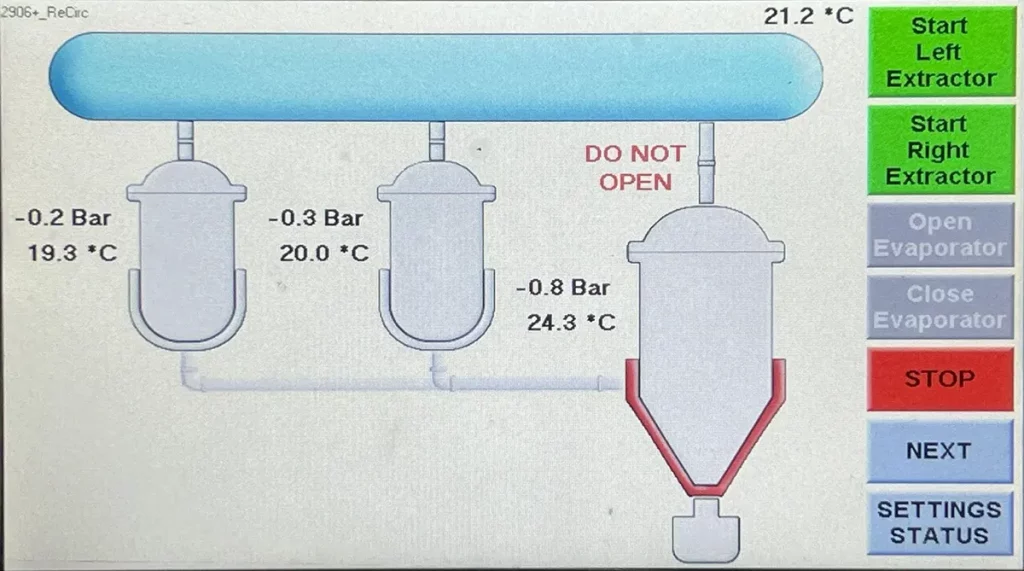

- The user-friendly control interface facilitates effective monitoring and control of the extraction process. The graphic interface on the left side shows color-coded indicators defining the state of each component. Blue stands for liquid, yellow for gas and red for heating component. The right side shows the system menu, featuring buttons for initiating left and right extractors, open and close the evaporator which is the vessel where extract is collected.

Detailed Menu Walkthrough

- Main Menu

- Extractor Visualization: Presents a visual display of the left/right extractor, separation and receiver vessels.

- Temperature & Pressure: Provides awareness by indicating the temperature and pressure of each extractor.

Configuration Screen

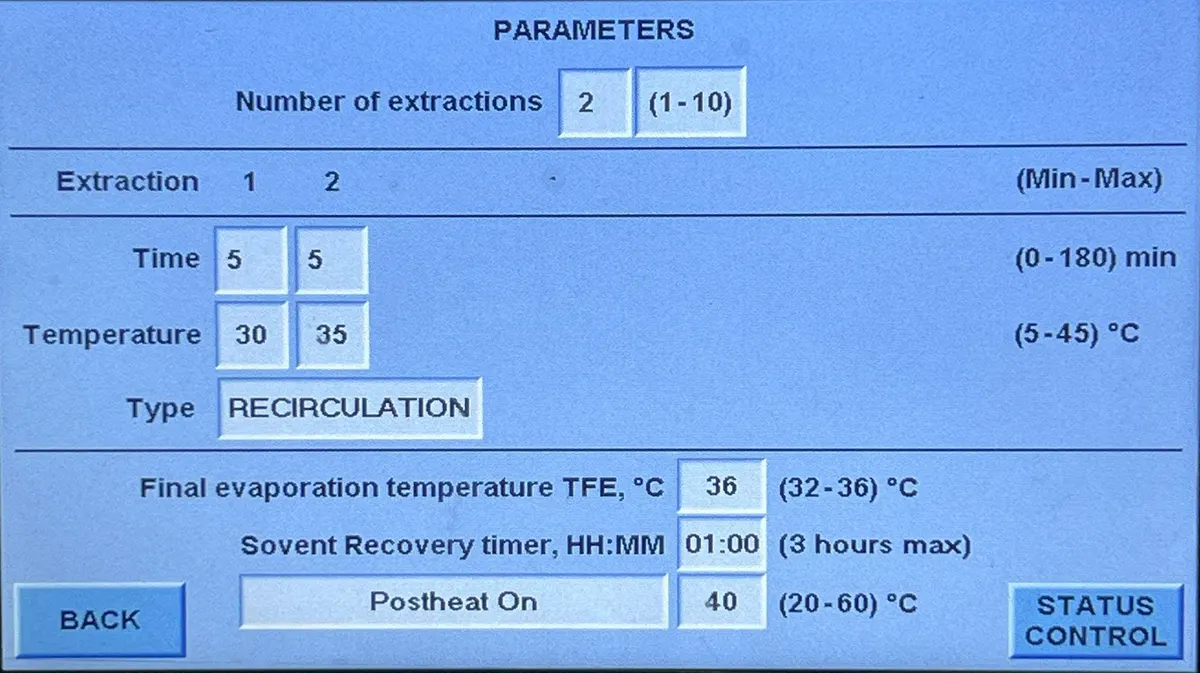

Configure main extraction parameters such as the number of extractions, time, and temperature for each cycle. As well select the main mode the extraction equipment is working under soaking or recirculation. If you plan to collect the extract on the next morning you can leave the post heat on. Specify the recovery time and temperature. Those parameters do not need to be change between extractions.

- Detailed Control Screen

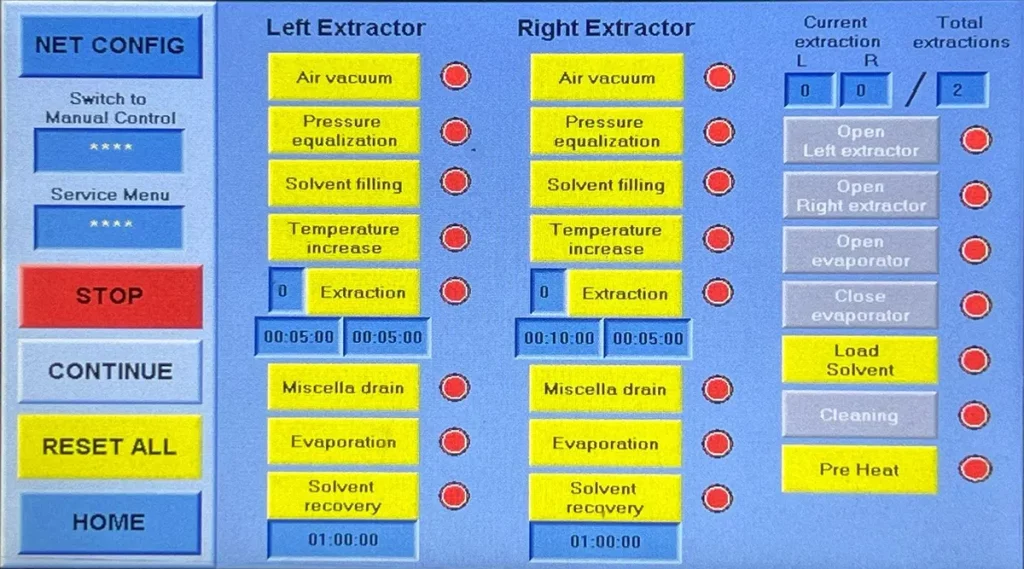

- Configuration Menu: Includes network configuration and password-protected compliance menus, offering options for reset, stop, and continue.

- Extraction Processes: Monitor the progress of each extractor through the visualization of green dots moving down each line.

- Service Menu: Perform occasional operations, including cleaning and solvent loading.

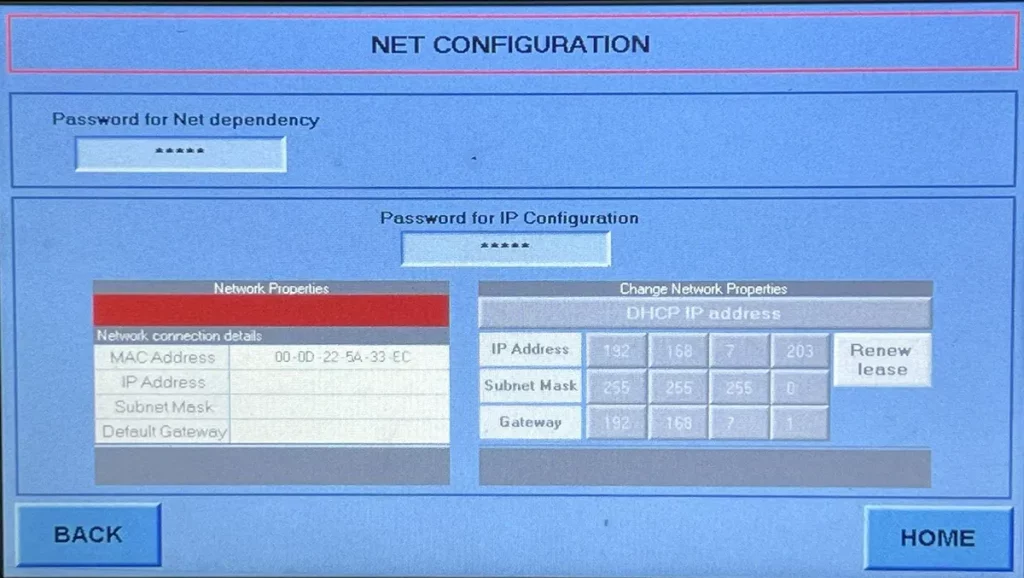

Network Connectivity

- Connect the PURE5™ 50 Liter Max System to the internet for remote monitoring and control via a network controller. This feature allows users to check machine status and control operations globally once connected to the local network.

CRC Filter

The 50L MAX is equipped with a CRC filter. Pack the cartridge with the desired media for remediating color, wax, heavy metals or other purpose media.

Conclusion

The PURE5™ 50 Liter Max R134a Aerosol Plant Extractor sets an industry standard for efficiency, automation, and user-friendly operation. Whether users are seasoned extractors or newcomers, the machines have a consistent interface across different models ensures a seamless experience. Explore the complete potential of extraction processes, employing top-notch cannabis equipment, with PURE5™!

Watch the introduction video: