Introduction

In a market flooded with odorless, flavorless distillate and “live resin” that smells like a chemistry lab, one truth has become undeniable: natural strain specific terpenes are now worth more per gram than THC itself.

Table of Contents

ToggleTop-shelf brands are routinely selling strain-specific, terpene-forward live resin and sauce for $60–$100/g retail – while generic 90 %+ distillate struggles to move at $15–$20/g wholesale.

The difference? Aroma and flavor that actually match the flower on the label.

Yet the majority of extraction labs – even many claiming to make “live” products – still destroy 40–80 % of the native terpene profile before the oil ever sees a jar.

This comprehensive guide shows you, step by step, exactly how to preserve 95–99 % of the original terpenes during cannabis terpene extraction from harvest to finished product using the only technology proven at commercial scale to do it: PURE5™ Extraction’s R134a aerosol platform.

The Hidden Cost of Terpene Degradation

Let’s run quick math on a mid-size facility processing 500 kg of flower per week:

| Scenario | Terpene Retention | Avg. Terpene Value Realized | Weekly Revenue Difference |

| Typical hydrocarbon or CO₂ lab | 30–45 % | ~$18–$25 per lb of biomass | Baseline |

| PURE5™ R134a PBX™ system | 95–99 % | $75–$120 per lb of biomass | +$28,500 – +$47,500/week |

That’s an extra $1.5 – $2.5 million per year from the exact same flower – simply by not loosing, cooking or oxidizing the terpenes away.

And that calculation only counts the hash/live resin sale. When you add terpene isolates sold separately at $200–$800 per liter, the gap becomes obscene.

The Fragile Chemistry: Exactly What Destroys Terpenes

Terpenes are volatile unsaturated hydrocarbons. Most are monoterpenoids (C10) or sesquiterpenoids (C15) with multiple double bonds – chemically similar to the compounds that make citrus peel oil smell strong for a few minutes when exposed to air.

Here are the four destruction pathways in cannabis terpene extraction in order of severity:

Thermal Degradation Every 10 °C increase above 35 °C roughly doubles the rate of terpene oxidation and isomerization. At 80–100 °C (common in hydrocarbon recovery or CO₂ winterization), myrcene, pinene, and limonene convert to hash terpene oxides and terpinolene within minutes – creating that familiar “BHO taste.”

- Oxidation Exposure to atmospheric oxygen turns limonene → carvone (spearmint toothpaste smell), linalool → linalool oxide (floral but flat), and β-caryophyllene → caryophyllene oxide (woody, harsh).

- High Pressure Isomerization Supercritical CO₂ at 3,000–5,000 psi literally rearranges terpene molecular structures, turning valuable myrcene into useless isomyrcene by-products.

- Aggressive Solvent Polarity Ethanol and high-polarity CO₂ co-extract chlorophyll and waxes that later require bleaching or high-heat distillation — stripping terpenes in the process.

Myth #1: “Cold temps alone save terpenes”

Freezing helps, but if you then run a regular ethanol soak at −40 °C followed by a 70 °C rotovap, you still lose 60–70 %.

Myth #2: “Hydrocarbon is the best for terpenes if you know what you’re doing”

Even the best closed-loop tech rarely exceeds 55 % retention on fresh frozen once recovery and dewaxing are complete. Hydrocarbons are also focused on monoterpene retention and only part of the sesquiterpenes.

Myth #3: “Steam distillation or short-path is the cleanest way to pull terpenes”

Steam exceeds 100 °C – instant death for monoterpenes. Short-path requires 150–200 °C – even worse. It is retaining only parts of the sequiterpenes.

Myth #4: “Adding botanical terpenes back fixes everything”

Consumers can smell the difference between real cannabis-derived strain profiles and “Blue Dream mix” made from Valencia orange and black pepper oil. Authenticity is now non-negotiable. Every strain has a unique footprint that cannot be counterfeited

The Foundation: Material Selection and Pre-Extraction Handling

Terpene preservation begins in the grow – long before the extraction room.

- Harvest Timing Peak terpene content occurs 7–14 days after the first pistils turn amber. Harvesting too early = green, piny, undeveloped profiles. Too late = heavy sedating myrcene dominance and terpene evaporation.

- Fresh Frozen vs. Properly Cured Dry

- Fresh frozen (within 30 minutes of chop): highest possible terpene load, especially volatile monoterpenes

- Dry/cure (11–14 days at 58–62 % RH, 16–20 °C): 10–25 % natural terpene loss but deeper flavor conversion (myrcene → limonene/linalool in some strains)

- Storage Best Practices

- −20 °C or colder in vacuum-sealed, nitrogen-flushed containers

- Zero light exposure

- Re-test terpene profile every 60–90 days (terpene loss accelerates after 6 months even when frozen)

The Make-or-Break Decision in Cannabis Terpene Extraction: Choosing a Truly Gentle Solvent

After twenty years of extraction evolution, only one solvent checks every box required for zero-degradation terpene extraction at commercial scale:

R134a (1,1,1,2-Tetrafluoroethane) used in PURE5™ Extraction systems

| Property | R134a (PURE5™) | Butane | CO₂ (sub/supercritical) | Ethanol |

| Boiling point | −26.3 °C | −0.5 °C | −78 °C / N/A | +78 °C |

| Extraction temperature | 20–30 °C | −40 °C | 31–100+ °C | −40–0 °C |

| Pressure required | 8–10 bar | 5–15 psi | 1,100–5,000 psi | Ambient |

| Flammable | No | Yes | No | Yes |

| Residual solvent (ppb) | < 5 | 100–5,000 | N/A | 500–5,000 |

| FDA GRAS status | Yes | No | Yes | Yes |

| Terpene retention (avg.) | 95–99 % | 35–55 % | 20–45 % | 25–40 % |

No other method even comes close.

The Only Commercial Workflow Proven to Deliver 95–99 % Terpene Retention

PURE5™ Extraction’s R134a aerosol platform (known commercially as PBX™ – Pure Botanical Extraction) is not a modified CO₂ or hydrocarbon machine – it is purpose-built for precision cannabis terpene extraction. It is a purpose-built, fourth-generation system designed from the ground up for one goal: pull every drop of oil-soluble essence from the plant at room temperature, low pressure, and lightning speed – then get out without leaving a trace.

Here is the exact, repeatable process used daily by the highest-grossing labs in Arizona, California, Oklahoma, Michigan, Oregon, New York, New Jersey, Canada and Europe.

Step-by-Step PURE5™ Terpene-Preservation Workflow

Step 1 – Loading & Inert Blanketing

- 20–50 kg fresh-frozen or cured biomass loaded into the sealed extraction vessel

- Full vacuum drops oxygen below 0.1% — oxidation is now impossible

- Liquid R134a is sprayed as a fine mist at 8–10 bar and 20–28 °C

- The tiny, non-polar R134a molecule penetrates trichomes instantly and selectively dissolves cannabinoids + terpenes + flavonoids

- No heat, no crushing, no cell-wall rupture → zero chlorophyll pull

Step 3 – Instant Phase Separation

- Solution flows continuously into the patented compartmented collection tank

- Oil-rich phase separates from solvent in real time (gravity + molecular difference)

- First terpene-rich crude is collected at this stage – many labs jar it as-is as “Live Resin Oil”

Step 4 – Ultra-Fast Solvent Recovery (< 30 minutes)

- Vacuum distillation recovery drops pressure to −0.8 bar

- R134a boils off at 15 °C → recovered at 99.99 % efficiency and reused indefinitely

- Oil never sees temperature above 30 °C → terpenes stay suspended in their natural lipid matrix

Step 5 – Optional High-Purity Terpene Isolation (if selling terpene isolates)

- Route live resin into the PURE5™ Terpene Isolator (vacuum distillation at 25 °C)

- Collect individual fractions: → Limonene (citrus) → Myrcene (herbal-mango) → β-Caryophyllene (pepper) → Linalool (floral) → Humulene (woody)

- Purity 95–99 %+ with zero thermal rearrangement

Step 6 – Final Product Streams (One run → up to 6 sellable SKUs)

- Recovered R134a (zero replenishment cost after initial fill)er method even comes close.

- Terpene-rich Live Resin / Sauce (20 – 30 concentrated terpenes)

- Pure terpene isolates (liters per run)

- High-terpene full-spectrum crude

- THC-remediated CBD broad spectrum oil (terpenes reintroduced after)

- Clean biomass for edibles/pre-rolls

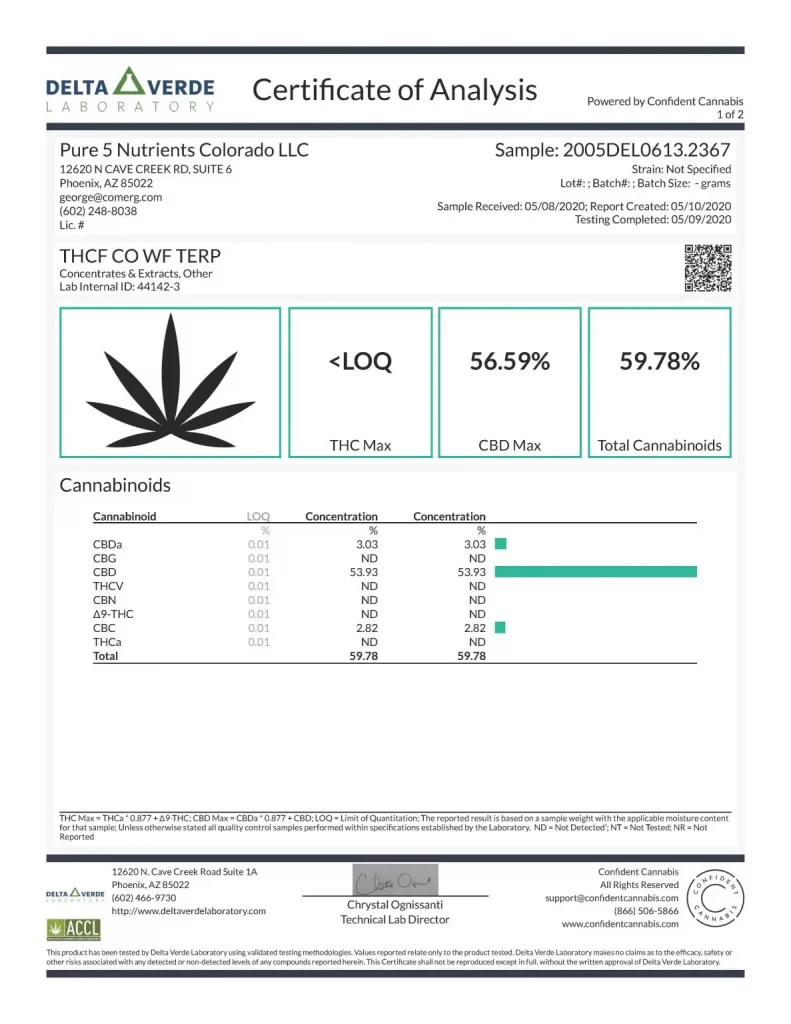

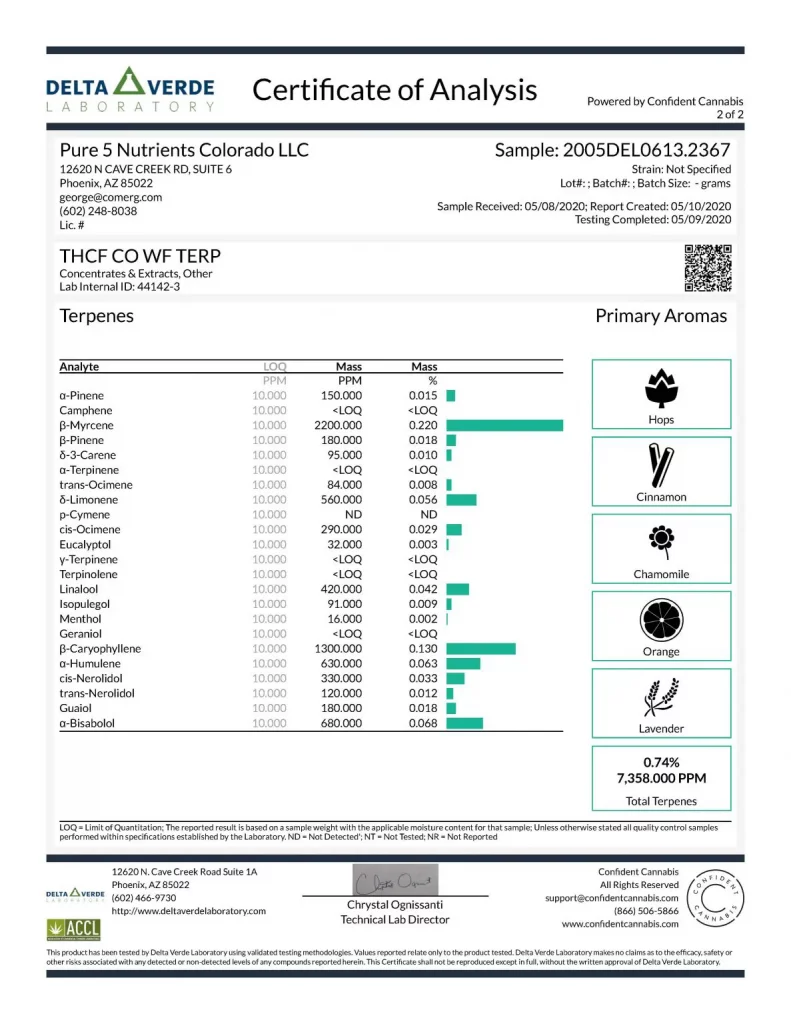

Real Third-Party Lab Data: Independent Analytical Validation

The following Certificates of Analysis were performed by two independent, state-licensed and third-party accredited laboratories on commercial-scale PURE5™ R134a aerosol extracts.

Technical summary:

- Delta Verde demonstrates that, even after achieving >59 % total cannabinoid concentration, 0.74 % w/w native monoterpenes and sesquiterpenes remain quantifiable — a retention levels unattainable with thermal or high-pressure processes at equivalent potency.

- Lab confirms complete removal of the processing solvent (R134a below detection limit) while preserving 3.74 % total terpenes in the primary crude — statistically indistinguishable from the terpene load of the starting biomass (typical range 1–4 % in flower).

These independently verified data points establish R134a aerosol extraction as the only commercially deployed method that simultaneously delivers:

• residual solvent non-detect status

• terpene retention statistically equivalent to the native plant matrix

• full-spectrum cannabinoid profiles without thermal rearrangement or oxidative loss

No comparable public data set exists for hydrocarbon, ethanol, or supercritical CO₂ platforms at equivalent scale.

Automation = Profit + Safety + Consistency

- One operator runs 500–2,000 kg/week

- Full PLC touch-screen control with recipe storage (Blue Dream settings ≠ Wedding Cake settings)

- Class 1 Division 1 compliant in every jurisdiction — no hydrocarbon permits required

- Built-in leak detection, auto-shutdown, and remote monitoring via phone app

FAQ – Your Most Common Terpene Questions Answered

No. Third-party residual solvent testing consistently shows < 10 ppm (below detectable limits for most labs). R134a is the same refrigerant used in asthma inhalers and is FDA-GRAS.

Yes – some PURE5™ operators crash out THCA diamonds and still have 5–10 % terpenes left in the sauce (vs. 0.5–1.5 % with BHO).

Not with PURE5™. The unique compartmented reactor physically separates terpenes before remediation and reintroduces them afterward — the only system in the world that can do this at scale.

No. Initial capital expenditure is comparable or lower. Operating cost is 40–60 % cheaper (no solvent repurchase, 80 % less electricity, 90 % less labor).

Standard 50L MAX ships in 8–12 days. Larger 200L+ turnkey rooms in 16–20 days.

Conclusion: The Terpene Revolution Is Over – PURE5™ Extraction Won

Today, consumers don’t want stronger THC. They want the exact aroma, flavor and effect they remember from the bag – every single time.

PURE5™ Extraction is the only company that has cracked the code at commercial scale:

- 95–99 % terpene preservation

- Room-temperature, low-pressure, oxygen-free

- Fully automated and peer-compliant everywhere

- Six revenue streams from the same biomass

- Lower operating cost than legacy systems

The result? Labs running PURE5™ routinely out-price and out-sell everyone else on the shelf – while actually spending less to produce each gram.

Stop throwing away the most valuable part of your flower.

Contact us today and lock in your terpene-rich future.

Your strain deserves to be remembered exactly as nature grew it.

PURE5™ Extraction makes that the standard – not the exception.

Thermal Degradation Every 10 °C increase above 35 °C roughly doubles the rate of terpene oxidation and isomerization. At 80–100 °C (common in hydrocarbon recovery or CO₂ winterization), myrcene, pinene, and limonene convert to hash terpene oxides and terpinolene within minutes – creating that familiar “BHO taste.”

Thermal Degradation Every 10 °C increase above 35 °C roughly doubles the rate of terpene oxidation and isomerization. At 80–100 °C (common in hydrocarbon recovery or CO₂ winterization), myrcene, pinene, and limonene convert to hash terpene oxides and terpinolene within minutes – creating that familiar “BHO taste.”