Cannabis extraction is a process that isolates specific compounds, like THC and CBD, from the plant material. This method can yield pure, potent concentrates like oils, tinctures, and waxes, which have diverse medical and recreational applications.

Table of Contents

ToggleExtraction is important because it enhances potency, ensures product consistency, and allows for precise dosing, making it more effective and safer for users. It also helps in reducing plant waste, enabling all parts of the cannabis plant to be utilized.

We’ll explore various techniques that transform raw cannabis into concentrated forms, revealing a universe of potency and flavor. From rosin press to CO2 extraction, discover how each method impacts the final product.

What are the Different Types of Cannabis Extraction Processes?

Some standard unique methods of cannabis extraction are alcohol, butane, CO2, cold water, and ethanol. All of these media help in separating cannabinoids from the cannabis plant. Each extraction method is unique and has its benefit, but the goal of each is to produce a highly potent end product.

Cannabis pure extracts are beneficial because extraction allows:

- Bigger cannabinoid purity

- Accurate dosing

- More stronger and longer-lasting concentrates

The most common usual cannabis extraction methods are:

1. BUTANE RESIN EXTRACTION

Butane hydrocarbon (BHO) extraction has been really highly researched and is used substantially in the food and perfume industry. The exact extraction method needs cannabis to be placed in a container before butane is slowly sprayed on cannabis to begin the extraction process.

The butane and the main cannabinoids are collected in another container.

When the BHO extraction method is used, the THC part of it remains around 60-70%.

2. SUPERCRITICAL CO2 EXTRACTION

CO2 extractions are non-toxic, eco-friendly methods of segregating the main cannabinoids from the whole cannabis plant. The exact extraction method leaves no traces of toxins behind and is additionally fully used in the following industries:

- Beer

- Coffee

- Fruit extracts

- Tea

The process is simple. 1st, supercritical CO2 is heated and passed through the fine milled cannabis flower. Then, the liquid part will pass through a separator to help remove the CO2 gas from the mixture.

As an eco-friendly method, the main gas is pushed through a condenser. Now, the gas gets really permitted to liquefy again and be recycled. Thus, it can be utilized for another extraction process in the future.

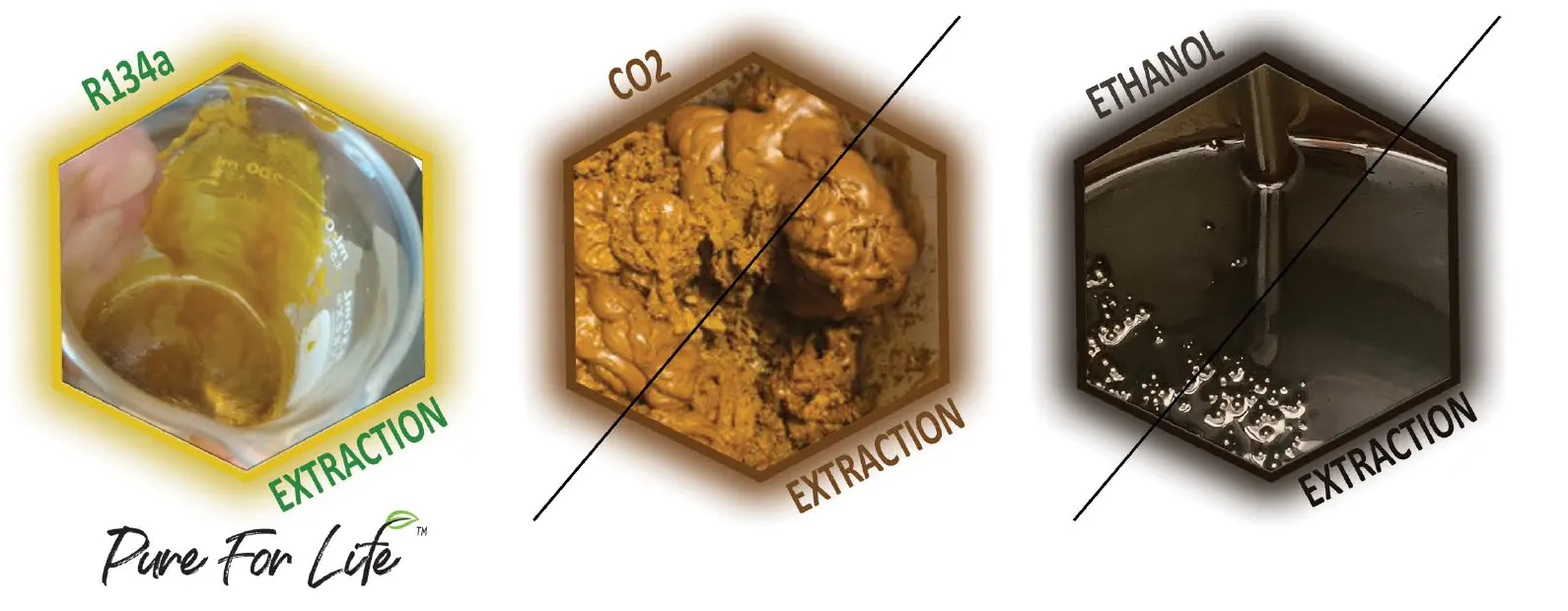

CO2 extraction requires a really precise build. However, it is an excellent method for making waxes and then oils after winterization.

3. ETHANOL EXTRACTION

The cannabis plant is soaked in ethanol to extract the THC.

The product is put through a distillation refining process as soon as it is extracted. It intensifies the concentration of the oil. Ethanol will remove desired compounds from the plant and will produce one of the purest concentrates of extract available leaving the terpenes behind.

The main objective of ethanol extraction is to ensure that the THC or CBD content is adequately extracted.

4. WATER EXTRACTION

Water extraction actually utilizes a solvent-free process of extraction that immerses the whole initially frozen cannabis plant in freezing water. The plant is then stirred in the cold water causing the trichomes to separate from the main plant.

Once the trichomes get fully separated from the plant, they pass through screens.

The end product has 51% to 71% THC levels.

5. ISOPROPYL OIL EXTRACTION

Isopropyl alcohol is necessary for this extraction method. Dried cannabis flowers are submerged in alcohol and then shaken gently. Isopropyl dissolves the oils from the plant.

All extracts should be appropriately stored and cooled to preserve shelf life and quality.

The extraction chillers maintain precision temperature control during the extraction process. On chilling properly, THC-A and CBD-A remain active. Chillers facilitate these main molecules to remain inert and unaffected by heat.

We understand that the cannabis extraction process needs to be followed with accurate chilling. Contact us for cheap extraction equipment for sale.

CONCLUSION

So far we have seen that almost any extraction method is either running at higher pressure and temperature extracting the solvent or has to be run at really low temperatures avoiding drawing fats, chlorophylls and lipids. This process harms the final oils and eliminates the properties of some of the good natural ingredients of the cannabis plant.

In PURE5™ we found a better option that does not require putting the solvent in extreme conditions to extract the flower that we call R134a aerosol extraction. It allows the final solvent to include all of the cannabinoid and terpenes. PURE5™ extraction delivers the full spectrum resin with full medical values at the lowest cost available on the market.

The PURE5™‘s extraction with R134a aerosol is performed at room temperatures and is able to separate the natural oils from the raw cannabis material in the most natural closed loop system.

The tetrafluoroethane gas is only slightly pressurized, and moved through the plant material then recovered in a different separation tank leaving only the full spectrum cannabis oil.

This separation method is safe for the human health and is non toxic, FDA & European Union approved it and qualified it as GRAS (Generally Recognized As Safe).

Most definitely R134a process is better, safer and cheaper than C02, Ethanol or any of the above extraction types. So if you want to use only the safest, most natural and the cheapest method of extraction – choose PURE5™’s extraction equipment. You can find out more about us and the process of Pure5™’s oil production here.