WHAT EXACTLY IS R134A EXTRACTION?

Utilizing R134a as a solvent is one of the newest technologies being used to increase the effectiveness of cannabis extraction. Because the R134a extraction technique can yield cannabis extracts with less than 5% wax concentration, these extracts are known as post-winterized full-spectrum oils. In most circumstances, the final product can have a wax content of as little as 2%. This means you do not need to winterize the extracted product unlike other extraction methods.

Table of Contents

Toggle

Most cannabis extractions tend to focus on targeting as much of the cannabinoids in the biomass as possible such as THC and CBD without much consideration to the flavor and aroma content, which is known to produce synergistic effects with the cannabinoids.

Researchers contend that consuming the entire spectrum of active chemicals rather than just cannabinoid isolates or distillates can enhance the therapeutic advantages while reducing the negative effects of the plant, a phenomenon known as the entourage effect. More of these chemicals preserved in concentrates and derivatives can result in a truly strain-specific product with strain-specific benefits.

Cannabis and hemp processors have been increasingly using R134a, a creative and effective solvent. In order to generate distinctive full spectrum goods, it is utilized to maintain the plant’s entire flavor and aroma profile. R134a is an affordable extraction method used to create high-potency extracts with high quality strain specific properties.

WHAT IS R134A?

At 214 F and 41 bar, the non-polar solvent R134a transitions to the supercritical state. Compare this to the 88 °F and 84 bar required for CO2 to attain its supercritical state.

It can be a highly effective approach to utilize for cannabis extractions since it uses nonpolar solvent and lower pressures, which prevents the deterioration of delicate flavor and aroma components.

It is non-toxic, odorless, inert, non-corrosive, and non-flammable to extract R134a. Additionally, when working with moist biomass, it does not produce an acid.

HOW DOES R134A EXTRACTION WORK?

Similar to CO2 extraction, R134a extraction passes through the material and changes the gas into a liquid in order to remove the plant’s active chemical components.

The extraction of R134a takes place in a closed-loop extraction system at low pressures and temperatures. Because of the low temperature of the method, there is no terpene loss during extraction or thermal degradation of the cannabinoids. Due to R134a’s low boiling point (-15F at 0 PSI), lengthy solvent recovery procedures that could slow down the operation and harm the final product are essentially unnecessary.

At room temperature, the solvent can easily off-gas from the extract to 0ppm giving you a consumable product with much less post processing than traditional extraction methods.

R134a is mildly pressurized and then passed over the biomass to extract the plant’s cannabinoids and terpenes.

A full-spectrum oil is then produced when the solvent is collected in a separation tank.

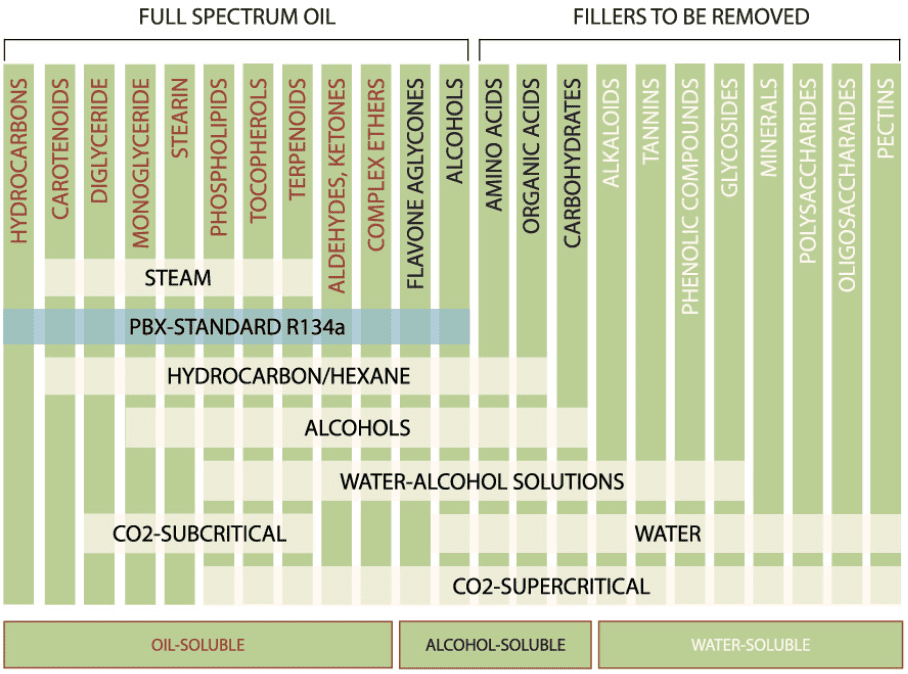

The graphic below shows bars representing the solubility of several solvents in addition to a variety of organic compounds. For the extraction of the full spectrum resin, understanding the solvent is crucial. It is crucial to choose your solvent base carefully when deciding what component to extract because plants have compounds that are soluble in oil, alcohol, and water.

EXTRACTION EFFICIENCY

R134a is a nonpolar, inert chemical that can efficiently extract desired components from a variety of biomass materials. The full terpene profile of the biomass may be preserved using this solvent without any degradation, which is the best part. Fresh plant material with a greater concentration of cannabinoids and terpenes is preferable for using in this extraction process.

R134a extraction is significantly simpler than CO2 extraction, requires less operator training, and nevertheless results in a high-quality extract. It is significantly more cost-effective because fewer technicians and systems are needed in the facilities, which results in lower maintenance and labor expenses.

According to research, R134a has a higher ability to dissolve unsaturated carboxylic acids and requires 2000% less energy to compress than CO2 extraction does under like circumstances.

Additionally, this extraction technique does not remove undesirable substances including pesticides, mold, and chlorophyll.

R134a is more than just an alternative to traditional extraction methods. Due to its extraction efficiency, affordability, ease-of-use, and purity we see it as the future of high-quality extraction.

PURE5™ Extraction Equipment would like to help you and your business succeed by providing a low-cost way to produce the highest quality extracts possible while keeping your employees and your investment safe from the dangers and high costs of flammable and toxic solvents. Click the link below to find out more.

Questions? View our FAQ or contact us at george@comerg.com