Apparatus Used in Solvent Extraction

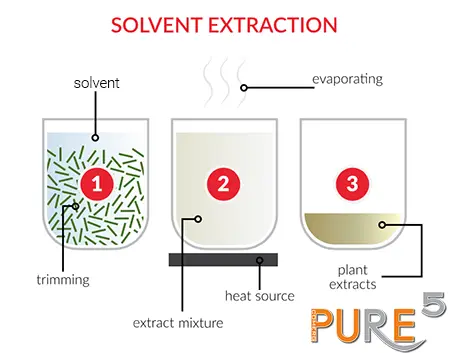

The most common apparatus used in solvent extraction is the closed-loop system. This system consists of several components including an extractor, condenser, collection vessel, vacuum pumps and chillers. This system relies on a specific temperature range and pressure that allows the solvent to bond with the desired compounds without damaging them. The extractor will contain the mixture of solvent and plant material while it is heated or cooled into a liquid state that allows for maximum extraction efficiency.

At PURE5™ Extraction in Phoenix Arizona we specialize in producing high quality products utilizing our unique R134A (aerosol) extraction process which does not require any additional chemicals or solvents for extracting cannabinoids like CBD oil from plants. We use room temperature and low pressure to extract the valuable Full Spectrum CBD oil with our patented method which makes us stand out from other companies who rely on traditional methods of heating or pressurizing solvents. This method also helps preserve all of the beneficial elements found in cannabis resulting in an end product that has higher quality than those produced by other methods of solvent extraction.

Extracting Cannabis With Closed Loop Systems

Closed loop systems are an excellent way to safely extract cannabis without damaging any of its beneficial elements. In addition to having a lower risk of fire or explosion due to its sealed nature, closed loop systems are also great for producing consistent results because they allow users to precisely control both temperature and pressure during extraction processes. The main downside of using closed loop systems is their cost; they tend to be much more expensive than open-loop systems due to their higher level of safety features built into their design.

Conclusion:

Solvent extraction is an essential process used by many companies including the cannabis industry where it is mainly utilized for extracting beneficial compounds such as CBD oil from plants without damaging any of their therapeutic properties during the process . When looking at what apparatus should be used it becomes clear that closed loop systems offer superior safety features as well as precision control over temperatures and pressures needed for successful extractions. However they do come at a higher cost compared to open loop setups. At PURE5™ Extraction, we specialize in using our one-of-a-kind R134A (aerosol) extraction method, which does not require any additional chemicals or solvents when extracting cannabinoids from plants, such as CBD oil. This sets us apart from other businesses that rely on conventional techniques. If you need help selecting what type of equipment best fits your needs don’t hesitate to reach out! We’d be happy to assist you!